NASA-funded AI technology enabling autonomous rovers and drones now keeps an eye on conveyor belts

Artificial intelligence software initially designed to learn and analyze Martian terrain is now at the heart of a system to monitor assembly lines on Earth.

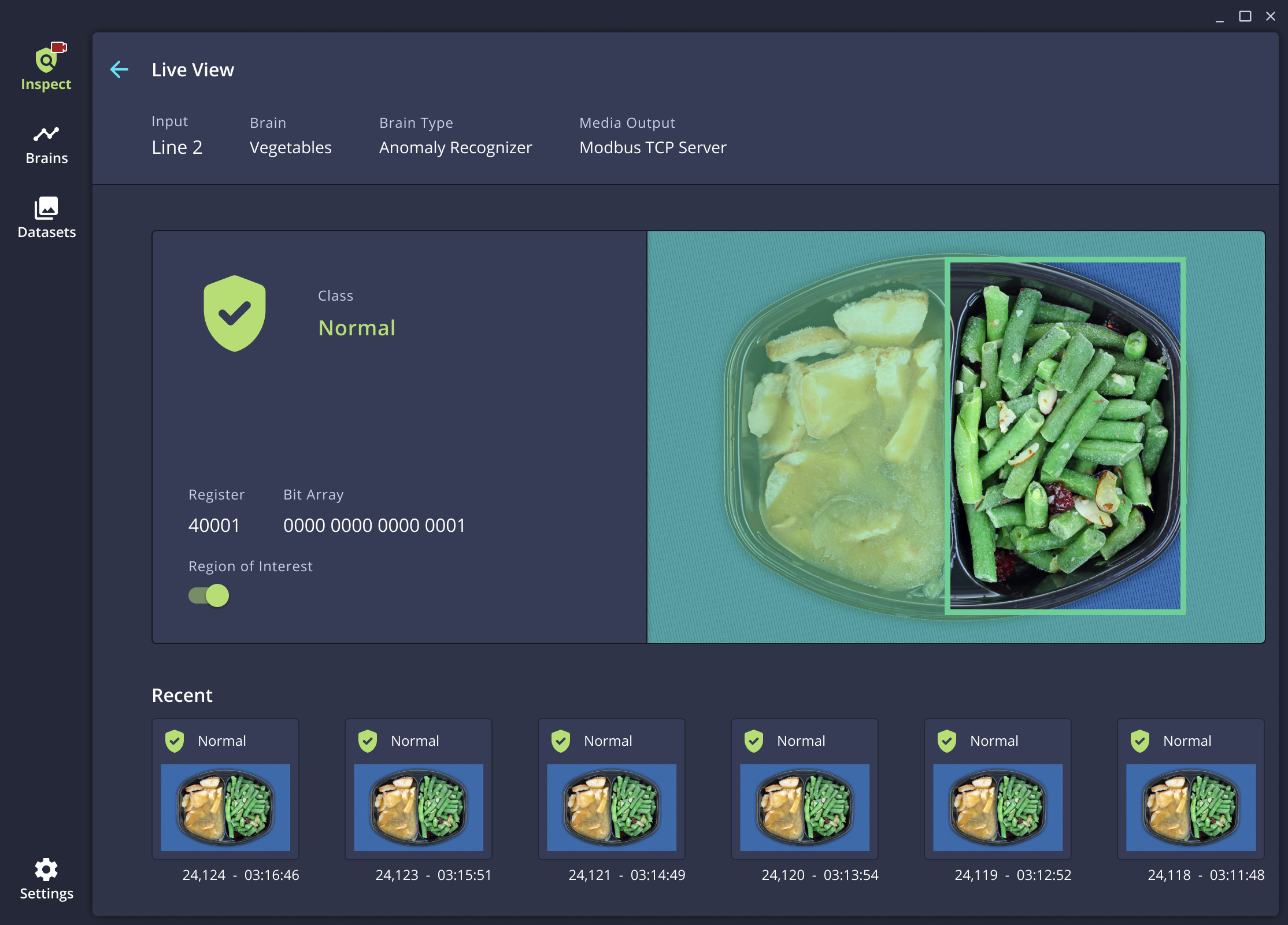

The vision inspection software from Neurala Inc., an artificial intelligence company in Boston, Massachusetts, works with existing cameras, computers, and even cellphones to monitor the quality of products running along a conveyor belt, for instance.

“Our software can learn very quickly on a processor with a very small footprint, a skill we learned working with NASA,” said Neurala cofounder and CEO Massimiliano Versace. “By doing so, we enable vision inspection with whatever components are already available, deploying in minutes. In our exploration of the market, we realized that the manufacturing space had a precise need for this technology.”

Versace and Neurala (Spinoff 2018) began working with NASA more than a decade ago on a project funded through the Small Business Technology Transfer (STTR) program. NASA was interested in “adaptive bio-inspired navigation for planetary exploration,” and Versace and his team had been working on neural network AI software modeled on the human brain.

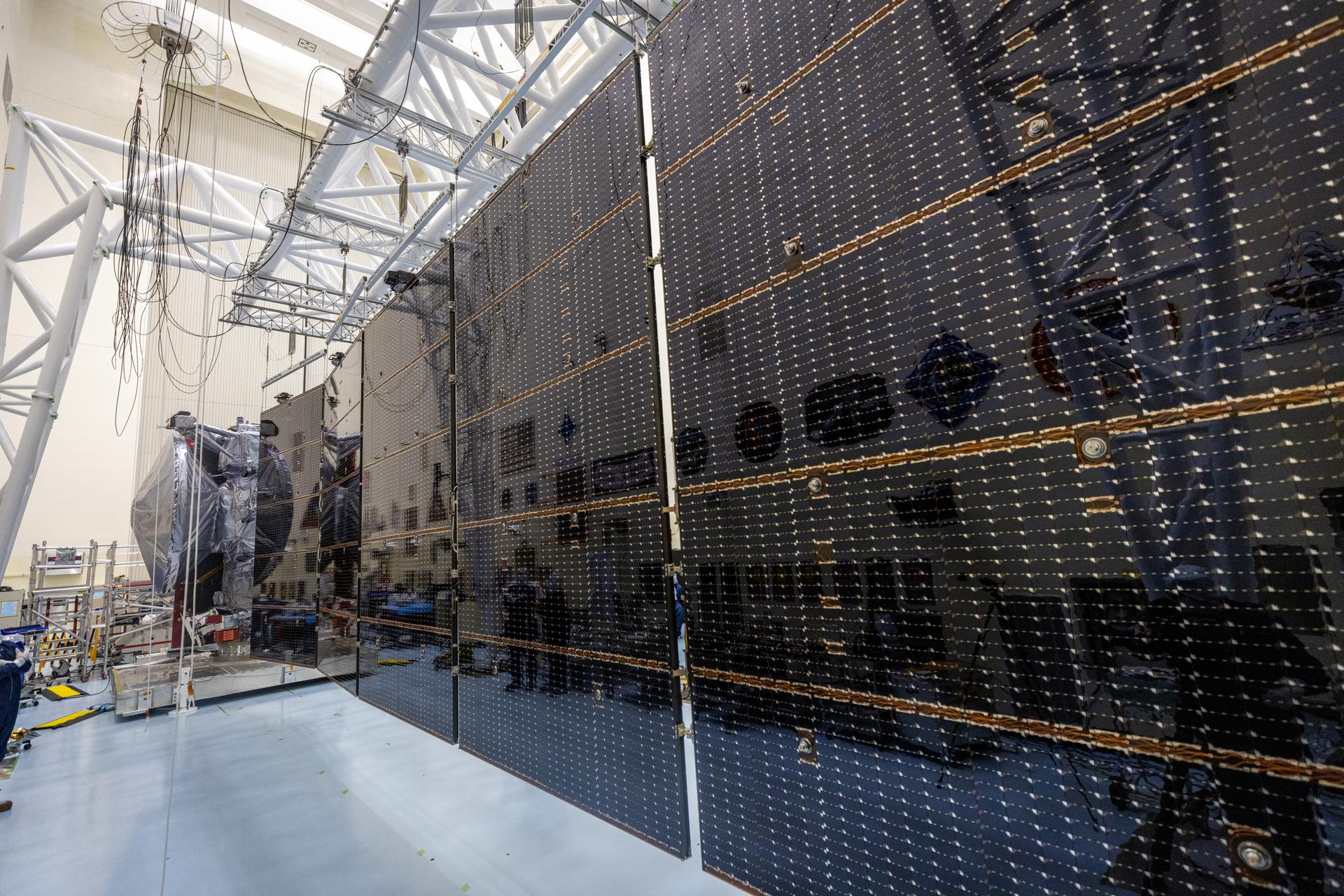

Focusing on a rover concept that could independently learn to traverse Martian terrain, Neurala went on to win STTR Phase II funding for the project. Additional money from a NASA Center Innovation Fund enabled the Neurala team to adapt its technology to drone navigation and collision avoidance.

In both the rover and the drone applications, the Neurala software could run on a small device on the vehicle itself, eliminating the delay of sending signals to a decision maker in another location. Since then, the company developed the software to help monitor assembly lines.

Onsite computing is an advantage in manufacturing, as well, where an assembly line may have a hundred items passing every minute, making visual inspections for quality control difficult.