Now Reading: SpaceX accelerates Starship launch preparations at Florida site for 2026 debut

-

01

SpaceX accelerates Starship launch preparations at Florida site for 2026 debut

SpaceX accelerates Starship launch preparations at Florida site for 2026 debut

SpaceX is rapidly advancing its Starship assembly and launch infrastructure at its Roberts Road site, as revealed by recent aerial photography from NSF. Progress is notable on several crucial elements, including the launch mount at LC-39A, the newly constructed launch tower’s chopstick arms, and the expansive Gigabay manufacturing facility.

The Space Coast is set to host the inaugural Starship launch in 2026, commencing from the historic 39A site, while preparations for two additional launch pads at SLC-37 are underway. Recent flyovers showcased the launch mount for LC-39A, which is now visible after its protective construction tent was removed to facilitate substantial crane work.

This mount is currently undergoing final installations essential for supporting the Super Heavy boosters, which will be powered by 33 Raptor engines. Observations indicated cranes installing a water manifold on the mount’s top deck, a system designed to mitigate heat during launches by using water-cooled steel technology, similar to systems used at Starbase’s Pad 2 in Texas.

The manifold, strategically placed in the staging zone for rockets, features a unique design to avoid interfering with the vehicle’s aft flaps. Nearby, another crane was lowering an actuator for the hold-down system, which helps stabilize and release the Super Heavy boosters. SpaceX might adopt a similar pre-installation method at LC-39A as was used at Pad 2 in Texas, where hold-down arms were set up prior to the pad’s rollout.

Additional preparations include the installation of structural supports for the Booster Quick Disconnects (BQDs), with components already staged for later assembly. Inside the construction enclosure, teams have been working on the lower assembly of the methane Quick Disconnect, essential for managing fuel transfer to the rockets. Cryogenic piping is also reportedly nearing completion for this system.

The groundwork for Starship operations is not limited to the launch mount. A significant portion of hardware for the tank farm intended for 39A is already staged near Hangar X2, emphasizing ongoing preparations for the site’s operational capabilities.

Moreover, development continues on the new launch tower at Roberts Road, with its chopstick arms, which were previously stored disassembled, now mainly welded together. Installation of necessary plumbing, electrical cables, and hydraulic systems has progressed, gearing the arms for their eventual integration into the launch tower. The first seven modules of the tower are completed, with interior outfitting now underway. These include essential amenities such as an emergency stair system and features that enhance functionality, differing from older designs that used larger gusset plates.

Construction at the expansive Gigabay facility is also pushing forward. In just a short span, two tower cranes have been erected to facilitate the assembly of beams and columns, with some sections reaching up to two stories high. The western half of the building is seeing concentrated development, possibly for preliminary storage and processing of Starship vehicles, while the eastern half remains unfinished.

Notably, plans to use NASA’s Vehicle Assembly Building for interim vehicle storage seem to have shifted, as SpaceX now appears focused on its own facilities. The company also continues to establish additional infrastructure, evident from the presence of several Cybertrucks parked in new lots nearby and potential future workstations spotted within the Gigabay.

With these developments, SpaceX is positioning itself for a historic series of launches, as the pace of construction and assembly at its Florida facilities accelerates in anticipation of the anticipated Starship missions.

Stay Informed With the Latest & Most Important News

Previous Post

Next Post

-

01Two Black Holes Observed Circling Each Other for the First Time

01Two Black Holes Observed Circling Each Other for the First Time -

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life -

03Thermodynamic Constraints On The Citric Acid Cycle And Related Reactions In Ocean World Interiors

03Thermodynamic Constraints On The Citric Acid Cycle And Related Reactions In Ocean World Interiors -

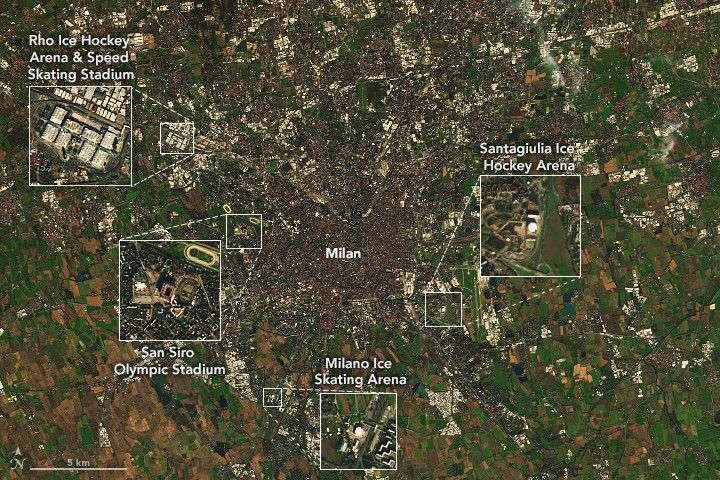

04Φsat-2 begins science phase for AI Earth images

04Φsat-2 begins science phase for AI Earth images -

05Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters

05Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters -

06Binary star systems are complex astronomical objects − a new AI approach could pin down their properties quickly

06Binary star systems are complex astronomical objects − a new AI approach could pin down their properties quickly -

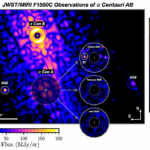

07Worlds Next Door: A Candidate Giant Planet Imaged in the Habitable Zone of α Cen A. I. Observations, Orbital and Physical Properties, and Exozodi Upper Limits

07Worlds Next Door: A Candidate Giant Planet Imaged in the Habitable Zone of α Cen A. I. Observations, Orbital and Physical Properties, and Exozodi Upper Limits