Now Reading: Science fiction and innovation in space

-

01

Science fiction and innovation in space

Science fiction and innovation in space

In this episode of Space Minds, Senior Staff Writer Jeff Foust moderates a panel at the Johns Hopkins University Bloomberg Center, the next installment of the Center’s Discovery Series.

The panel brings together leaders from Astrobotic, Apex, Johns Hopkins APL and Stoke Space to explore how ideas once confined to the pages of science fiction are rapidly becoming reality. From commercial lunar landers and factory-scale satellite production to nuclear-powered rotorcraft bound for Titan and fully reusable rockets designed to fly daily, the space industry is undergoing a transformative moment.

The panel discusses the technologies driving this surge—lower-cost launch, advanced autonomy, shrinking spacecraft, and the rise of a vibrant commercial ecosystem. They also examine the future of lunar infrastructure, in-orbit manufacturing, national security needs, and the growing competitive pressure from China. It’s a wide-ranging conversation about innovation, challenges, and the new frontiers emerging as space becomes more accessible than ever.

Moderator: Jeff Foust

Panelists:

- John Thornton — CEO, Astrobotic

- Wes Puckett — VP Government Strategy, Apex

- Bobby Braun — Space Exploration Sector Head, Johns Hopkins APL

- Devon Papandrew — VP Business Development, Stoke Space

Show notes and transcript

Click here for Notes and Transcript

Time Markers

00:00 – Introduction: When science fiction becomes science fact

00:41 – A technology that changed everything

04:25 – Panel introduction

06:29 – The elevator pitches

11:16 – Astrobotic’s Griffin lander

15:46 – Why satellite manufacturing needs an automotive mindset

19:08 – Dragonfly mission: Flying a nuclear-powered rotorcraft on Titan

23:17 – Reusable rockets designed for daily flights

26:44 – Are they competing with SpaceX?

29:25 – What changed? Key innovation inflection points of the last decade

37:46 – AI and autonomy: Real applications in spacecraft, design & operations

44:20 – How government R&D fuels commercial breakthroughs—and vice versa

46:13 – What about China? Competition, motivation & risk

52:24 – What’s the most exciting thing in space right now (besides their own work)?

Transcript – Panel Conversation

This transcript has been edited-for-clarity.

Jeff Foust – I invite the panel to come up on the stage here. We’re talking about innovation and emerging capabilities. Earlier, Mike mentioned the influence that science fiction has had on luminaries like Elon Musk and Jeff Bezos. I was one of those people too—I just didn’t become a billionaire. Growing up in the ’80s, without the internet, I turned to books and especially science fiction to imagine future possibilities: lunar landers run by companies, fleets of satellites, fully reusable rockets, asteroid deflection. Today in 2025, the people on this panel are doing all of these things. Science fiction is becoming reality.

So for the next 50 minutes or so, we’ll explore what these organizations are doing and look broadly at innovation in space—key technologies enabling today’s rapid expansion, the challenges ahead, and what the future might hold. I’ll ask each panelist to give a short elevator pitch before we dive deeper. John, start us off.

John Thornton – Great. Thank you. Astrobotic is in the business of making space accessible to the world. The big thing we’re known for is our lunar landers. We flew our first one a year and a half ago. It didn’t get all the way to the Moon, but we learned a lot—spent ten and a half days in space, tested every piece of our system, fixed what didn’t work, and now we’re preparing for our next flight in mid-2026. That mission will carry a 500-kilogram rover to the south pole of the Moon.

We’re also building a power grid for the lunar poles called LunaGrid—one of the biggest things emerging right now to make the Moon sustainable. And here on Earth, we’re developing reusable rockets, starting small and scaling up. That’s Astrobotic in a snapshot.

Jeff Foust – All right. Wes?

Wes Puckett – I’m Wes Puckett, Vice President of U.S. Government Strategy at Apex. We’re laser-focused on the manufacturing problem. We see scale as the huge knob that needs turning in the space industry. It’s straightforward to get one demonstration mission working these days, but if you haven’t designed for manufacturability or solved your supply chain, suddenly it takes two to three years to reach scale.

We solve that problem. We want to create infrastructure that lets payload providers get to space with minimal friction. That enables broader proliferation across the industry.

Jeff Foust – Bobby?

Bobby Braun – Thanks, Jeff. I’m Bobby Braun from the Johns Hopkins Applied Physics Lab. APL is a defense and national security lab with a significant civil space footprint, primarily for NASA but also NOAA. We build one-of-a-kind, first-of-a-kind space science missions. We collaborate with industry but tackle big science and technology challenges that haven’t been done before—like the DART asteroid deflection mission or Dragonfly, a mission to Titan to search for the origins of life.

We develop technologies, scientific theories, and share them broadly to strengthen the U.S. economy. And we do a lot of work in national security space, which has grown significantly.

Jeff Foust – Devin?

Devon Papandrew – Stoke Space is building 100% reusable rockets designed to fly daily. Both the first and second stages return to the launch site to be rapidly reused—operated more like commercial aircraft than disposable hardware. We believe this can deliver routine, reliable, low-cost access to space.

We’ve raised about a billion dollars, have major commercial and government contracts, and have been building hardware fast. We’re nearly done reconstructing Launch Site 14 at Cape Canaveral—the old John Glenn pad. We aim to bring it all together for our first launch next year.

Jeff Foust – John, you’re developing the Griffin lander you want to launch next year. Give the audience a feel for where things stand and what the mission will do.

John Thornton – Griffin is being built at our headquarters in Pittsburgh. You can actually see it through the glass at the Moonshot Museum. Right now, the structure is complete. Tanks are staged and ready. Avionics and solar panels are waiting to be integrated. Propulsion lines are welded—thin-wall titanium tubes are hard, but they’re done. Over the next few months, we’ll finish integration and send the lander to NASA Glenn for environmental tests—thermal vacuum, vibration, EMI, RFI—and then ship it to the Cape.

It’s a large lander using the full capacity of Falcon Heavy. After trans-lunar injection, we control the trajectory, enter lunar orbit, descend, land, deploy payloads, and operate for 5–10 days. It’s short because lunar night gets extremely cold—liquid-nitrogen cold for two weeks. Batteries fail. Electronics fail. LunaGrid will eventually solve that; for now, this mission demonstrates large-scale mobility with a partner-built rover at the lunar south pole.

Jeff Foust – And you had to pivot because NASA changed the plan for the payload. What did you have to adjust, and who wants to send things to the Moon?

John Thornton – This mission began in 2020 under NASA’s CLPS program—Commercial Lunar Payload Services. NASA buys end-to-end commercial delivery to the Moon. Griffin originally carried NASA’s VIPER rover. NASA later pulled VIPER and moved it to a different lander.

We were lucky to find a similar payload from Astrolab. Astrobotic and Astrolab teamed up, and their rover will now fly with us instead. When VIPER came off, we asked who wanted to go to the Moon—within a very short time, 60 groups from around the world knocked on our door. Demand is increasing dramatically.

Jeff Foust – Wes, satellites used to be bespoke. You’re building assembly-line satellites. How?

Wes Puckett – We want to apply automotive-style manufacturing to satellites—efficient assembly lines, optimized supply chains, and designs built for manufacturability. Think of our satellite buses as the vans or trucks you’d buy to operate any business. We want them to be the accessible tools you use to get your mission done.

We offer transparent pricing on our website, downloadable CAD files, user guides, and multiple configurations to fit most missions while still manufacturing a single part number. Reusable launch has dropped costs, and we aim to be the next layer of infrastructure enabling space proliferation.

Jeff Foust – And who’s buying these satellites?

Wes Puckett – A healthy mix of commercial and government customers. Demand matches our manufacturing ramp.

Jeff Foust – Bobby, let’s talk about Dragonfly. What will the mission do, and what are you developing to make a rotorcraft fly on Titan?

Bobby Braun – Dragonfly is as NASA as it gets—a flying vehicle, a science mission, and a technology mission. Titan is an ocean world like early Earth. We’re sending instruments to study the chemical building blocks of life. The vehicle is powered by a radioisotope generator feeding a battery that runs science instruments, flight systems, and telecom.

There are no other spacecraft at Titan, so we must communicate directly with Earth. That requires autonomy: choosing landing sites, managing power, selecting instruments. Over three-plus years, Dragonfly will travel a distance roughly from Washington, D.C. to New York across Titan’s surface.

Jeff Foust – Devin, fully reusable rockets seem logical—we don’t throw away parts of airplanes. Why is it so hard?

Devon Papandrew – Upper-stage mass is the big challenge. Every kilogram you devote to reusability is one less kilogram of payload—the thing you get paid for. So the economics look bad at low flight rates.

But high cadence changes everything. The biggest cost driver in launch is your fixed overhead. If you only fly a few times a year, prices must be high. With rapid reusability, you can amortize costs across many flights.

The other challenge is refurbishment. The Space Shuttle was reusable, but refurbishment was so costly and slow that you might as well have built a new orbiter each time. We solve this through actively cooled heat shields—robust, resilient, tolerant to real-world conditions. Land, refuel, refly.

Jeff Foust – SpaceX is also building full reusability with Starship. Are you competing with them?

Devon Papandrew – Anyone in launch competes with SpaceX—they’re dominant. But we’re medium-lift. Starship is ideal for Starlink and Moon/Mars missions. There’s huge unmet demand among third-party constellations—communications, Earth observation, SIGINT, national security. Those customers need something in our class.

And while Starship may reduce costs, it won’t necessarily reduce prices. Competition is what lowers prices. That’s where we come in.

Jeff Foust – What’s changed in the last 10 years that created today’s inflection point?

John Thornton – Lower launch costs, greater belief in lunar missions, a shift in perception. Years ago, saying we’d land on the Moon got us laughed at. Not anymore. Demand is rising fast—60 groups wanted a lunar ride when VIPER moved off our lander. People see resource potential: water ice that can become rocket fuel. The Moon is the gateway to using space resources and expanding the economic sphere beyond Earth.

Bobby Braun – Spacecraft are getting smaller, and rideshare has opened opportunities. Compute keeps increasing, enabling autonomy—Perseverance chose its own landing site; Dragonfly will autonomously pick landing sites every time. Cheap launch, small spacecraft, and powerful computing are fueling rapid growth.

Devon Papandrew – Falcon 9 reusability and rideshare made proliferated constellations economically viable. The next era includes more launch players, more routine access, and microgravity manufacturing. Huge value is possible—materials, biotech, pharmaceuticals. But you need downmass. Many samples die waiting for return capacity. That’s why reusable upper stages matter.

Wes Puckett – Launch cost drops enabled many missions. We want to be the next enabler—making it easy for people to get to space. GEO will also get cheaper, opening new opportunities.

Jeff Foust – How are you using or considering using AI?

Wes Puckett – In design and software development. And as constellations grow in crowded LEO, autonomy for collision avoidance becomes essential.

Bobby Braun – We use AI widely, including for materials discovery. Autonomy is key for missions like Dragonfly.

John Thornton – We use autonomy for landers and AI for data processing—there’s a petabyte of lunar data out there. AI could identify resource hotspots. We’re exploring design applications too.

Devon Papandrew – We use AI in tools for building and testing rockets, though much is deterministic. Application-layer customers may use it more heavily.

Jeff Foust – How have public-sector innovations helped you? And Bobby, how do you integrate private-sector innovation?

John Thornton – Astrobotic is a Carnegie Mellon spinout. Autonomous car research translated directly to lander work. SBIR/STTR funding was foundational—we exist because of it.

Wes Puckett – We want to make it easier to test technologies in space. More space experimentation accelerates progress.

Devon Papandrew – Our first revenue was a Phase I SBIR from NSF—foundational. Private investment accelerated once government interest became clear.

Bobby Braun – Absolutely. APL thrives on integrating innovations. We license tech—like Rocket Lab’s Frontier-X radio, which originated at APL. We also partner with Intuitive Machines on cislunar navigation.

Jeff Foust – What about China?

John Thornton – China is aggressive on the Moon—first to land on the far side, exploring resources, pushing human missions. Yes, it’s competition, but competition accelerates progress—like the U.S.–Soviet race. It focuses investment and galvanizes innovation.

Wes Puckett – Apex recently announced a self-funded demonstration for space-based interceptors—defensive, not destructive. A resilient space architecture is vital.

Bobby Braun – China is a peer competitor. But I’ll take the U.S. space industry and talent against anyone. It’s a motivator.

Devon Papandrew – SBI systems require many interceptors in many orbits, which requires lots of launch. To stay competitive, we need routine, reliable access to space.

Jeff Foust – What is the most interesting thing happening in space right now—other than your own work?

John Thornton – The massive investment flowing into space. It’s fueling activity across the board.

Wes Puckett – Space-to-space optical communications.

Bobby Braun – Space-based power generation. With enough power and compute, we could have data centers in space. Also, I’m bullish on a robotically tended south-pole lunar base.

Devon Papandrew – Lunar infrastructure.

Jeff Foust – Unfortunately, we’re out of time. Thank you to our panelists and everyone who helped organize this event—please join the reception in the lobby.

About Space Minds

Space Minds is a new audio and video podcast from SpaceNews that focuses on the inspiring leaders, technologies and exciting opportunities in space.

The weekly podcast features compelling interviews with scientists, founders and experts who love to talk about space, covers the news that has enthusiasts daydreaming, and engages with listeners. Join David Ariosto, Mike Gruss and journalists from the SpaceNews team for new episodes every Thursday.

Watch a new episode every Thursday on SpaceNews.com and on our YouTube, Spotify and Apple channels.

Be the first to know when new episodes drop! Enter your email, and we’ll make sure you get exclusive access to each episode as soon as it goes live!

Space Minds Podcast

“*” indicates required fields

Note: By registering, you consent to receive communications from SpaceNews and our partners.

Stay Informed With the Latest & Most Important News

-

01Two Black Holes Observed Circling Each Other for the First Time

01Two Black Holes Observed Circling Each Other for the First Time -

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life -

03Astronomy 101: From the Sun and Moon to Wormholes and Warp Drive, Key Theories, Discoveries, and Facts about the Universe (The Adams 101 Series)

03Astronomy 101: From the Sun and Moon to Wormholes and Warp Drive, Key Theories, Discoveries, and Facts about the Universe (The Adams 101 Series) -

04True Anomaly hires former York Space executive as chief operating officer

04True Anomaly hires former York Space executive as chief operating officer -

05Φsat-2 begins science phase for AI Earth images

05Φsat-2 begins science phase for AI Earth images -

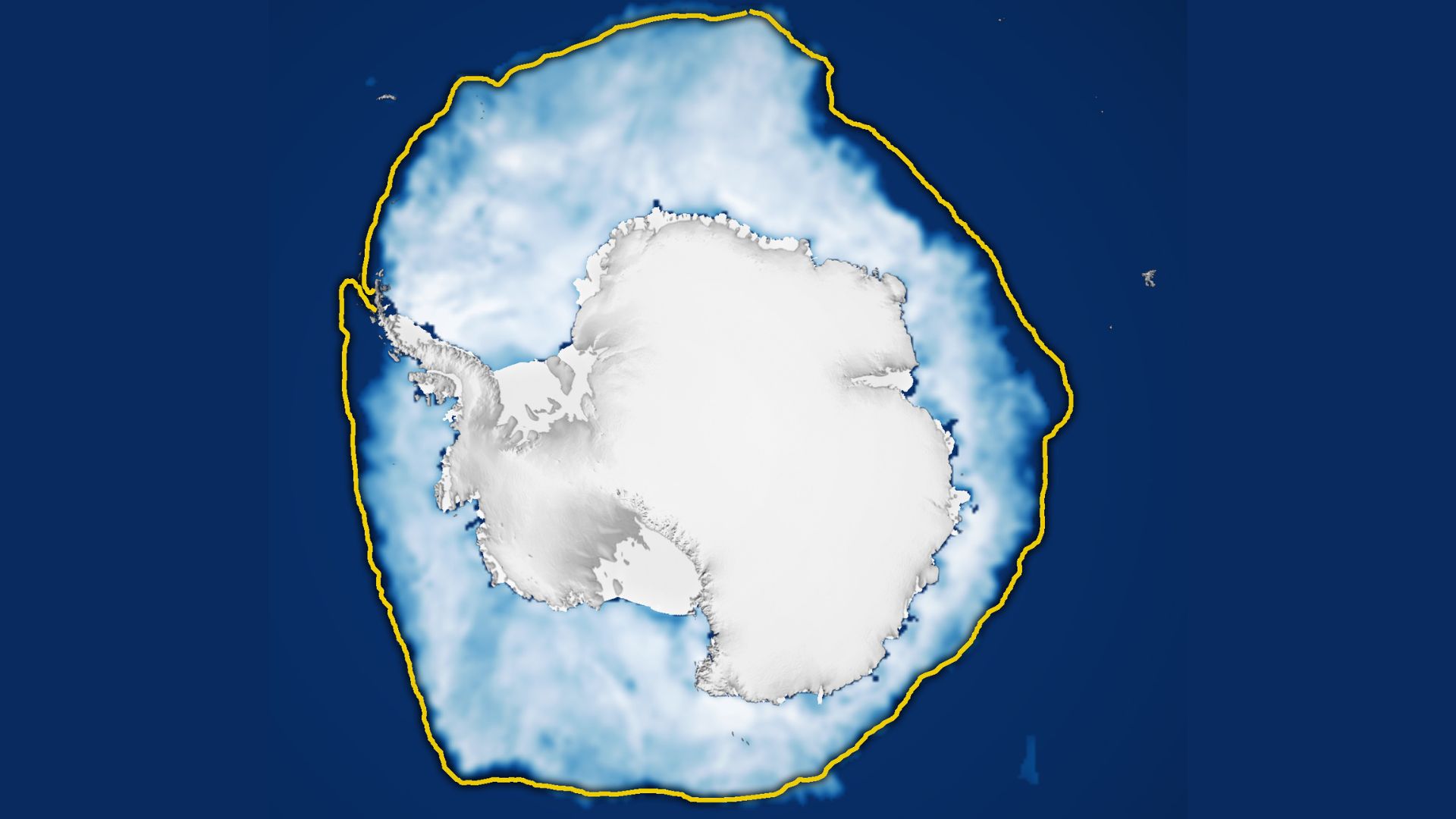

06Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters

06Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters -

07Binary star systems are complex astronomical objects − a new AI approach could pin down their properties quickly

07Binary star systems are complex astronomical objects − a new AI approach could pin down their properties quickly