Now Reading: Northrop Grumman continues solid rocket motor development and test program

-

01

Northrop Grumman continues solid rocket motor development and test program

Northrop Grumman continues solid rocket motor development and test program

WASHINGTON — Northrop Grumman tested a solid rocket motor Dec. 4 as part of an internal program to advance solid rocket propulsion technologies.

The company conducted a static-fire test of a motor called SMASH!22 at its Promontory, Utah, facility. The motor fired for about 30 seconds, and Northrop later declared the test a success.

SMASH!22 is a 22-inch (56-centimeter) diameter motor in a configuration the company calls Solid Motor Adaptable, Scalable, Half Time/Cost. It was developed to test new manufacturing approaches and materials intended to reduce production time and cost for missile and space applications.

Northrop developed SMASH!22 under its Solid Motor Annual Rocket Technology Demonstrator, or SMART Demo, program, which seeks to test new solid motor technologies annually. The company started SMART Demo in 2023 and conducted another test in August.

Through SMART Demo, the company is “taking on more technical risk” than in a traditional development program, said Jim Kalberer, vice president of propulsion systems at Northrop Grumman, during a call with reporters before the latest test.

“We bring on new materials from new suppliers, things that are not typically part of or have not historically been part of proven rocket motor development, and we do that so we can find new ways to move with speed,” he said.

For this test, the company went from a clean sheet to a critical design review in eight months. “Typically, a solid rocket motor design and test effort would take three years” to make the same progress, he said.

The company has already seen returns from the effort, including a low-cost propellant from an earlier SMART Demo test. “We have identified places where that will be inserted into existing products, but it also positions us to offer affordable solutions,” Kalberer said.

The program has also tested a new robotic approach to motor development. “We spray a liner inside the rocket motor. In the past that has been a hand operation,” he said. “These robotic processes allow us to more quickly and efficiently remove touch labor and apply liners to the inside of the case.”

The SMASH!22 motor used a steel case produced with new welding and manufacturing methods, along with 3D-printed components. It also used the low-cost propellant previously demonstrated.

The motor, he said, is similar in size to those used on interceptor missiles and sounding rockets, but there are no plans to incorporate it into any specific Northrop products. “What we do is work with our customers to understand emerging requirements and then demonstrate a flight-relevant size that we believe could meet those requirements, so it may have more than one application as the technology moves forward.”

Northrop said it has also developed a second motor as part of this phase of the SMART Demo program: a 29-inch Bombardment Attack Missile Motor called BAMM!29 2.0. That motor is scheduled for a test firing in early 2026.

Stay Informed With the Latest & Most Important News

Previous Post

Next Post

-

01Two Black Holes Observed Circling Each Other for the First Time

01Two Black Holes Observed Circling Each Other for the First Time -

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life -

03Thermodynamic Constraints On The Citric Acid Cycle And Related Reactions In Ocean World Interiors

03Thermodynamic Constraints On The Citric Acid Cycle And Related Reactions In Ocean World Interiors -

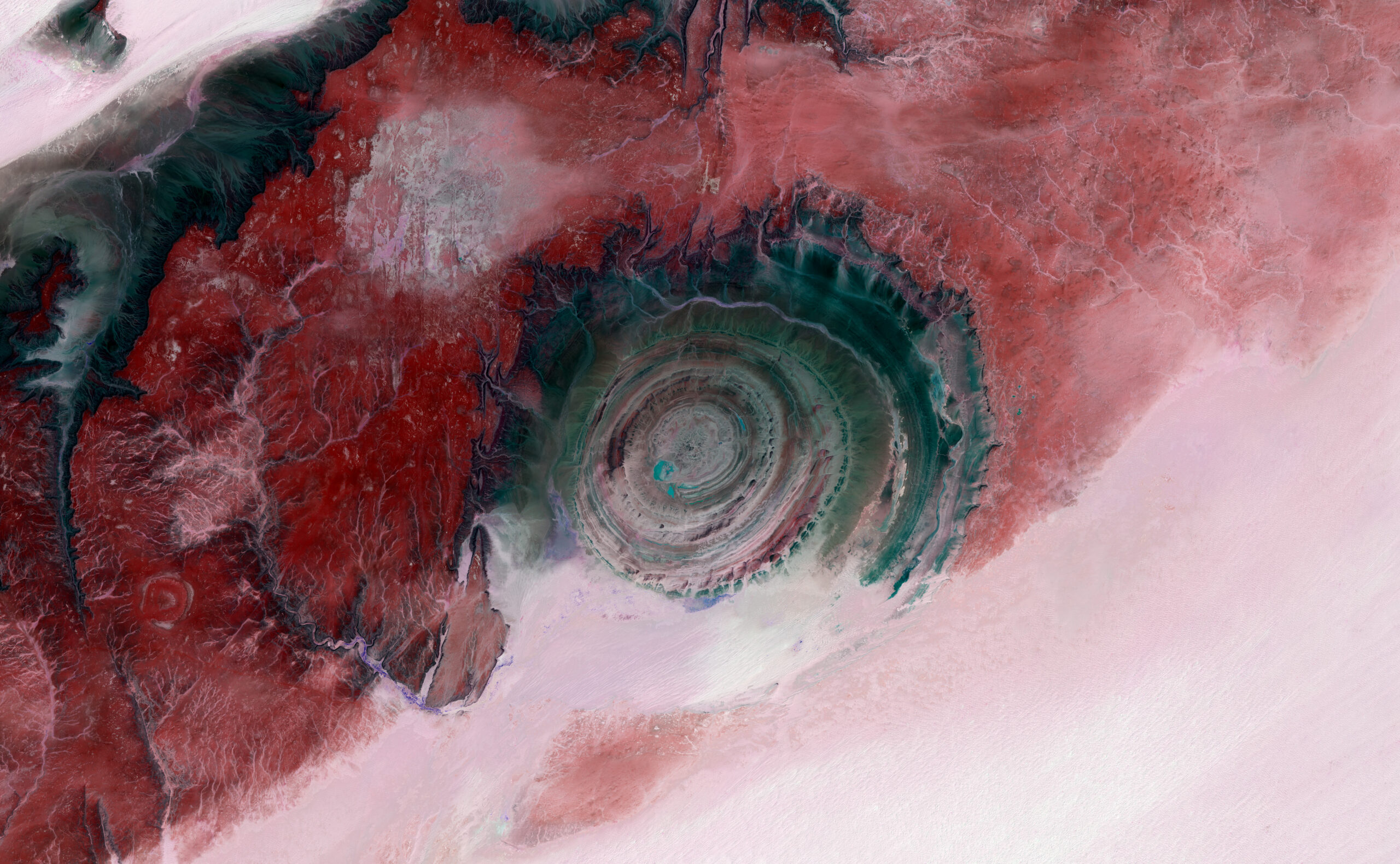

04Φsat-2 begins science phase for AI Earth images

04Φsat-2 begins science phase for AI Earth images -

05Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters

05Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters -

06Binary star systems are complex astronomical objects − a new AI approach could pin down their properties quickly

06Binary star systems are complex astronomical objects − a new AI approach could pin down their properties quickly -

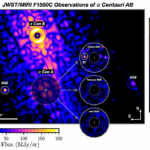

07Worlds Next Door: A Candidate Giant Planet Imaged in the Habitable Zone of α Cen A. I. Observations, Orbital and Physical Properties, and Exozodi Upper Limits

07Worlds Next Door: A Candidate Giant Planet Imaged in the Habitable Zone of α Cen A. I. Observations, Orbital and Physical Properties, and Exozodi Upper Limits