Now Reading: The “Stealth” Strategy Pays Off: UARX Space Emerges as Europe’s High-Reliability Powerhouse

-

01

The “Stealth” Strategy Pays Off: UARX Space Emerges as Europe’s High-Reliability Powerhouse

The “Stealth” Strategy Pays Off: UARX Space Emerges as Europe’s High-Reliability Powerhouse

NIGRÁN, Spain — While much of the European NewSpace ecosystem has spent the last five years in a cycle of public fundraising and prototype announcements, UARX Space took a different path. Founded in 2020, the company remained in a self-imposed stealth mode, focusing on the rigorous engineering required to reach Technology Readiness Level 9 (TRL9) across its entire product line.

“Operating in stealth allowed us to focus on engineering fundamentals without the pressure of the hype cycle,” says Yanina Hallak, CEO of UARX Space, who holds a Ph.D. in Aerospace Engineering. “Our strategy was simple: don’t announce until you can deliver. We didn’t want to come to market with a promise; we wanted to come with a catalog that has already been to space.”

Today, that period of quiet development is yielding significant commercial and institutional dividends. Following a string of successful deployments and high-profile recognition from the European Space Agency (ESA), the Spanish logistics provider is positioning itself as a rare breed in the startup world: a company that leads with flight heritage rather than speculation.

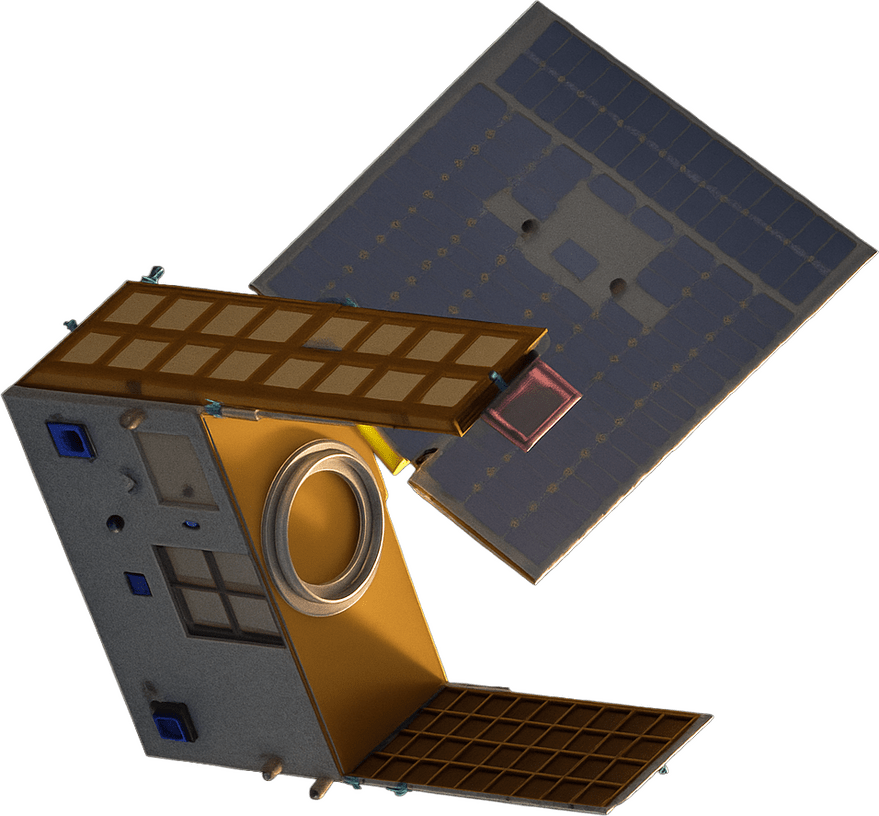

OSSIE: A Multipurpose Platform for In Orbit Validation

Beyond the traditional concept of a space tug, OSSIE (Orbit Solutions to Simplify Injection and Exploration) is a modular, high performance spacecraft engineered to serve as a versatile platform for the new era of orbital operations. While much of the sector focuses on the last mile delivery problem for mega constellations, a task OSSIE performs with precision using its high performance green propellant chemical propulsion, its true value lies in its capacity as a premier laboratory for In Orbit Demonstration (IOD) and In Orbit Validation (IOV).

The inaugural mission of the vehicle serves as a testament to this versatility, carrying seven international and national customers alongside the proprietary technological developments of UARX. By offering a stable, maneuverable, and power rich environment, OSSIE provides innumerable opportunities for entities to validate disruptive technologies in a real space environment, ranging from altitude and inclination adjustments to complex phasing maneuvers that were previously cost prohibitive for smaller operators.

A significant milestone for the platform is the recently announced partnership with Dawn Aerospace. On its maiden flight, which is currently manifested for mid 2026, OSSIE will carry a Docking and Fluidic Transfer (DFT) port. This hardware foundation will eventually enable in orbit refueling and servicing, which aligns with the ESA Zero Debris Charter, of which UARX is a committed signatory.

“OSSIE represents the coming of age for Spanish space engineering,” says Hallak. “We are providing a sovereign European capability that ensures our customers aren’t just getting to orbit, but are getting to the exact orbit they need to maximize their revenue and mission life. By controlling the entire stack, we eliminate the ‘integrator’s tax’ and pass that efficiency to the operator.”

The Avionics Core: Vertical Integration and cPCI Serial Space

At the heart of OSSIE’s performance is a level of vertical integration rarely seen in a company of UARX’s size. While many OTV developers act as integrators of third-party black boxes, UARX has developed its entire avionics suite in-house. This internal control is the key to their TRL9 reliability.

The company’s high-reliability avionics box is built on the cPCI Serial Space standard. This modular backplane architecture is a ruggedized version of the industrial CompactPCI Serial standard, optimized specifically for the harsh radiation and thermal environments of space. By adopting an open-standard architecture, UARX ensures that its systems are both scalable and interoperable.

“We made a strategic decision to build our own electronics because the ‘black box’ approach limits your ability to optimize for the mission,” explains Andrés Villa, CTO and Co-founder, also a Ph.D. in Aerospace Engineering. “Our avionics are based on the cPCI Serial Space standard, which gives us a modular, high-speed backplane capable of supporting everything from SpaceWire to TTEthernet. This allows us to offer a level of redundancy and data-handling capability that usually only exists in much larger, more expensive institutional satellites.”

This proprietary On-Board Computer (OBC) and avionics suite allow OSSIE to coordinate complex autonomous maneuvers with a level of precision that off-the-shelf components simply cannot match. For UARX, the avionics are the “brain” that enables the “muscle” of their propulsion systems to function flawlessly in the most demanding mission profiles.

SAU&RON: Proving Reliability in Off-Nominal Conditions

While OSSIE is the flagship, the SAU&RON line of separation systems is the company’s commercial workhorse. Designed as a “low-shock” alternative to traditional pyrotechnic systems, SAU&RON utilizes proprietary actuators to ensure a gentle, precise release of the payload, a critical requirement for sensitive optical or scientific instruments.

The reliability of these systems was unintentionally but definitively proven during the recent PSLV C62 mission. UARX provided a SAU&RON 8” system for Orbital Paradigm’s entry capsule. Despite a significant failure in the launch vehicle’s upper stage, telemetry confirmed that the UARX hardware survived the extreme vibration and off-nominal loads of the event. Crucially, the system successfully executed the separation of the re-entry capsule, allowing the customer to collect vital flight data for three minutes during its descent.

“In this business, a success under off-nominal conditions is often more valuable than a success under perfect ones,” says Villa. “The PSLV C62 mission proved that our hardware has the engineering margins to handle the worst possible day at the office. When the rocket fails but the separation system still works, that tells the customer everything they need to know about our quality.”

This reputation led directly to a major commercial contract with Atmos Space Cargo GmbH. The German company has contracted UARX to provide SAU&RON 24” for their Phoenix 2 re-entry capsule. This contract validates UARX’s ability to scale their technology for high-mass, high-value payloads that are critical to the emerging in-space manufacturing market.

RAMI and the Interplanetary Frontier

The UARX portfolio extends beyond separation rings. The RAMI CubeSat deployer (up to 12U) has already earned its heritage on the inaugural flight of Ariane 6, but its design represents a leap beyond standard LEO deployers.

RAMI is the first deployer of its kind conceived from the ground up for interplanetary missions. Unlike traditional “dumb” deployers that merely act as mechanical ejection tubes, RAMI offers a sophisticated charging and communication interface with the hosted CubeSat. This allows the satellite to remain fully charged and undergo health checks during long-duration transits to the Moon, Mars, or beyond, a capability that is essential for the next decade of deep-space exploration.

Alongside RAMI, the company offers STAR, a modular structure for satellites in the 50–200 kg class for those looking into satellites bigger than 12U, and Pockettino, a dispenser designed for PocketQubes. This diversity ensures that UARX is a comprehensive logistics partner capable of supporting a payload from the lab to the final orbital slot, whether that slot is 500 km above Earth or in a lunar trajectory.

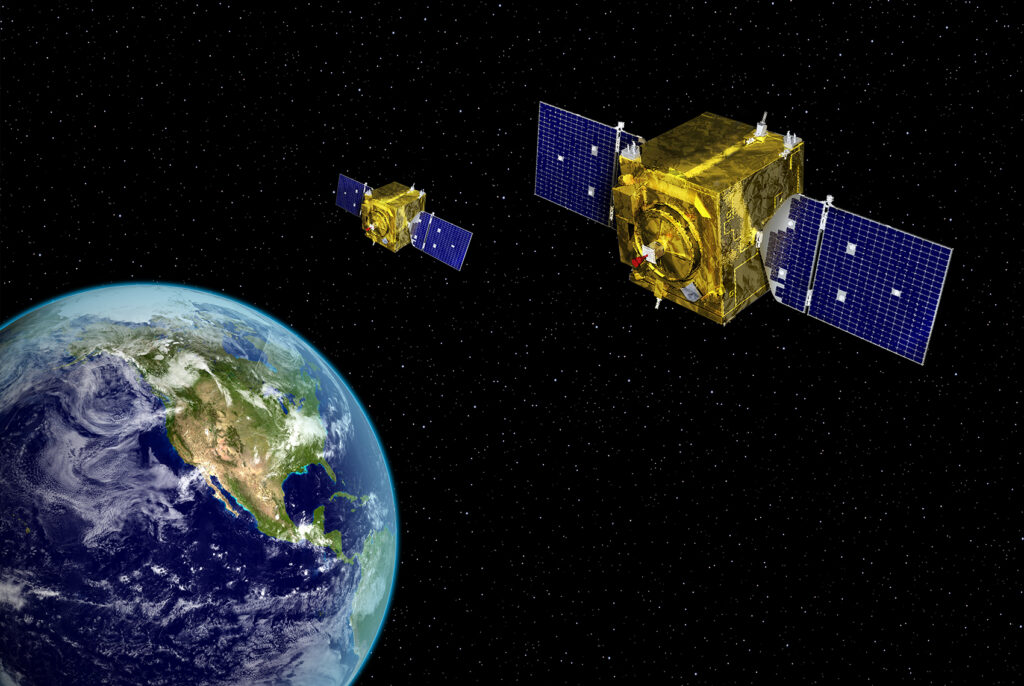

The Strategic Pivot: From OTVs to Dual-Use Platforms

UARX is now leveraging the “lessons learned” from OSSIE to expand into a new, high-growth market: small satellite platforms. This transition is a natural evolution; an OTV is essentially a highly capable, propulsion-heavy satellite bus designed to deliver other spacecraft. By stripping away the secondary deployment mechanisms, UARX can offer a robust, maneuverable bus for dedicated missions.

The company is now offering these platforms for Dual-Use applications, catering to both commercial and defense sectors. In late 2025, the Spanish Ministry of Defense officially categorized the entire UARX product line as Dual Use. This certification confirms that UARX’s technology meets the stringent standards required for national security infrastructure.

“Transitioning our OTV technology into satellite platforms is about providing a rapid-response capability for the defense sector,” says Juan Pablo Franco, COO of UARX Space. “An OTV and a defense-grade satellite bus share the same DNA: they both require high-reliability avionics, sovereign software, and the ability to maneuver precisely in contested environments. By building these platforms in-house, we are helping Europe achieve strategic autonomy.”

These platforms are ideal for Earth Observation and Signals Intelligence (SIGINT), where the ability to maneuver the satellite’s orbit provides a tactical advantage. By using the same cPCI Serial Space avionics across all platforms, UARX ensures that defense customers receive a flight-proven, radiation-tolerant-by-design “brain” for their most critical assets.

Institutional Endorsement: The ESA Rising Star Designation

The company’s first five years of operation reached a significant milestone at Space Tech Expo Europe 2025 in Bremen, where UARX Space was officially named an ESA Rising Star. This designation, awarded by the European Space Agency’s Commercialisation Directorate, serves as a high-level institutional recognition of the company’s strategic importance within the European space ecosystem.

Rather than a “culmination,” the award acts as a formal validation of the path UARX has carved since its inception. By selecting UARX as one of the most promising scale-ups in Europe, ESA has signaled that the company’s “reliability-first” approach is exactly what the continent needs to secure its commercial and strategic interests in orbit. The recognition offers UARX facilitated access to ESA’s commercialization services, investor matchmaking, and a seat at the table for defining future European space logistics standards.

For UARX, the Bremen announcement was less about reaching a finish line and more about the industry finally catching up to the work they had been doing in the shadows. It acknowledges half a decade of silent, high-performance development and provides the “institutional seal of approval” necessary to transition from a high-tech startup to a cornerstone of the European launch supply chain.

The Industrial Engine in Galicia

Behind these technical achievements is an impressive industrial infrastructure. UARX recently expanded its headquarters to a 1,200 m² facility in the Porto do Molle Tech Park in Nigrán, Galicia. This site is unique in the region, featuring ISO 7 and ISO 8 clean rooms and the capacity to integrate up to six OSSIE OTV units simultaneously.

This facility represents the “industrialization” phase of UARX. The company is moving beyond prototyping into mass production of its SAU&RON separation systems and RAMI deployers to meet the surging demand from partners like Atmos Space Cargo and Orbital Paradigm.

A Team Defined by Pedigree

The “reliability-first” culture at UARX is a direct reflection of its leadership. Founders Yanina Hallak (CEO) and Andrés Villa (CTO) both hold PhDs in Space Engineering and are alumni of California Polytechnic State University (CalPoly), “the legendary birthplace of the CubeSat standard”. Their tenure at CalPoly allowed them to learn the standard from its creators, an experience they have combined with over a decade of experience in traditional geostationary and Earth observation missions.

Joining them in leadership is Juan Pablo Franco (COO), whose background includes multiple master’s degrees in critical technology, artificial intelligence (AI) and business management. Together, they have built a team that views space not as a place for “move fast and break things,” but as a domain where technical excellence is the only true currency.

Conclusion: Scaling for the 2027 Era

UARX Space’s five-year silence was not a sign of inactivity, but a period of intense preparation. By prioritizing technical rigor and sovereign electronics development before seeking the spotlight, the team in Nigrán has built a foundation that is remarkably resilient.

As the company prepares for the mid-2026 launch of OSSIE and the rollout of its dual-use satellite platforms, its mission remains fixed. In an orbital environment that is becoming increasingly crowded and contested, the industry needs partners who can handle the “unplanned stress test” and still deliver the payload.

“We are engineers first,” Hallak concludes. “Everything we do, from the cPCI Serial Space backplane in our computers to the proprietary actuators in our SAU&RON rings, is about reducing risk for the customer. Space is hard, but it doesn’t have to be uncertain.”

With a clear roadmap toward industrialization and a growing list of flight-proven successes, UARX Space has proven that sometimes, the best way to move fast is to start by being very quiet and very thorough.

Stay Informed With the Latest & Most Important News

Previous Post

Next Post

-

01Two Black Holes Observed Circling Each Other for the First Time

01Two Black Holes Observed Circling Each Other for the First Time -

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life -

03Thermodynamic Constraints On The Citric Acid Cycle And Related Reactions In Ocean World Interiors

03Thermodynamic Constraints On The Citric Acid Cycle And Related Reactions In Ocean World Interiors -

04Φsat-2 begins science phase for AI Earth images

04Φsat-2 begins science phase for AI Earth images -

05Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters

05Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters -

06Binary star systems are complex astronomical objects − a new AI approach could pin down their properties quickly

06Binary star systems are complex astronomical objects − a new AI approach could pin down their properties quickly -

07Worlds Next Door: A Candidate Giant Planet Imaged in the Habitable Zone of α Cen A. I. Observations, Orbital and Physical Properties, and Exozodi Upper Limits

07Worlds Next Door: A Candidate Giant Planet Imaged in the Habitable Zone of α Cen A. I. Observations, Orbital and Physical Properties, and Exozodi Upper Limits