Now Reading: Europe Advances in Reentry Technology Through ATMOS Innovations

-

01

Europe Advances in Reentry Technology Through ATMOS Innovations

Europe Advances in Reentry Technology Through ATMOS Innovations

The landscape of spaceflight is continuously evolving, and Europe is positioning itself as a key player, particularly within the scope of reentry technology. This evolution is primarily fueled by innovative endeavors like those of ATMOS Space Cargo, which is pioneering the development of advanced reentry vehicles designed to make returning payloads to Earth more accessible and efficient.

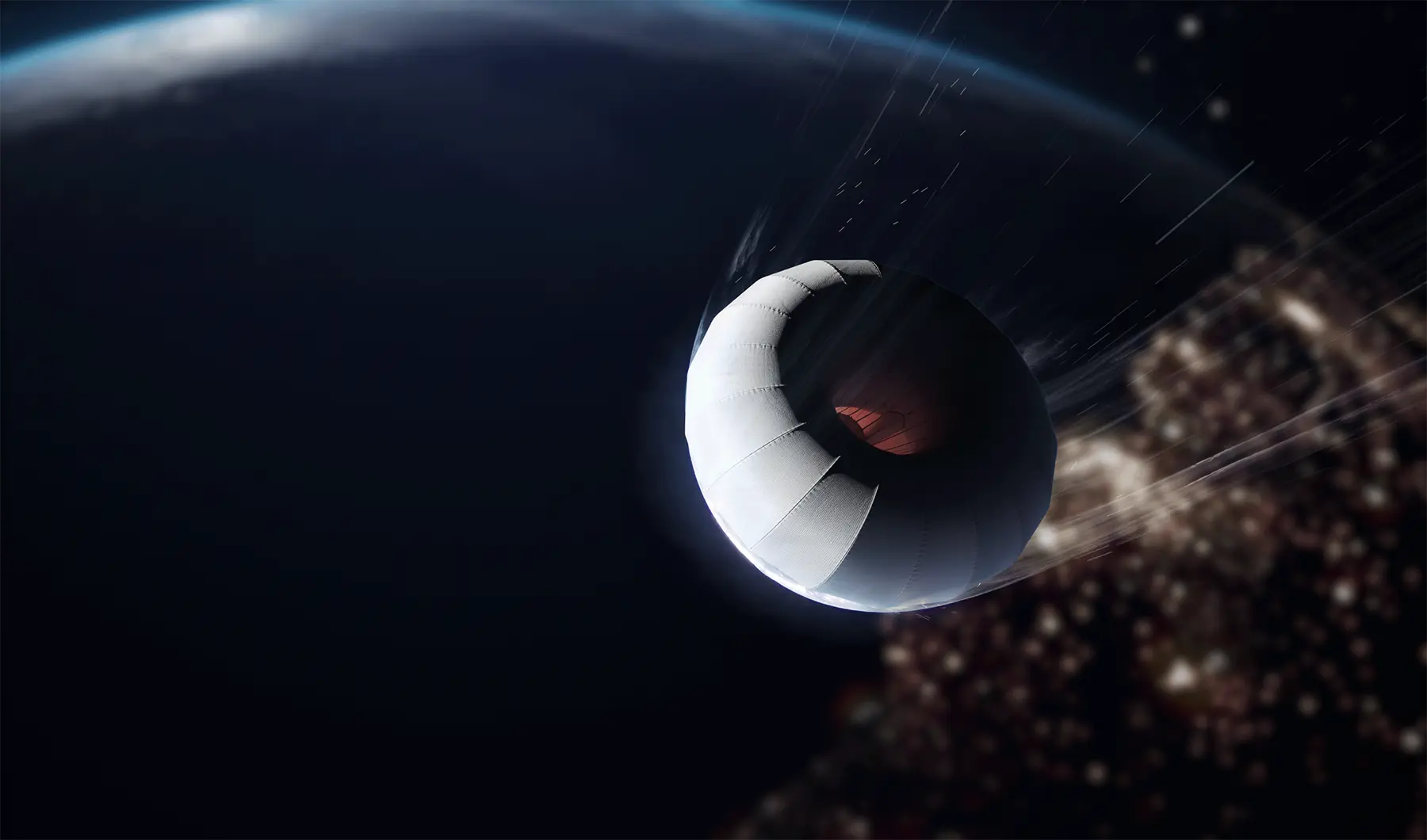

One of the remarkable aspects of ATMOS’s approach is its foundation in cutting-edge developments from past missions, notably the inflatable heat shield technology derived from NASA’s LOFTID project. With successful demonstrations in hypersonic reentry, these systems are not only innovative but potentially transformative for European space logistics. The ability to return payloads reliably and economically will be critical as Europe expands its footprint in the commercial space arena, particularly in low-Earth orbit (LEO) operations.

As ATMOS continues to test and refine its Phoenix capsules, the implications for the European space industry are profound. The future of reentry technology in Europe could see significant advancements in payload capacity, technology integration, and reasonable investment operations. ATMOS aims to develop reentry capabilities that are not only reusable but also tailored to accommodate a broader array of scientific and commercial payloads.

The market for space-based research and commercial operations is rapidly growing, with organizations worldwide seeking reliable methods for returning experiments, equipment, and even entire satellites to Earth safely. ATMOS’s focus on payloads typical to the International Space Station (ISS) serves as an example of how the company intends to cater to the needs of various sectors, notably biomedical research. Emerging technologies such as 3D printing of human tissues, protein crystallization, and advanced materials research benefit from timely returns, making the ability to retrieve these payloads integral to further advancements.

Furthermore, the overarching goal of promoting a rideshare service from space back to Earth illustrates ATMOS’s commitment to democratizing access to space. As noted by Sebastian Klaus, the company’s founder and CEO, the strategy aims to provide opportunities for academic institutions and smaller research entities to deploy experiments in space and retrieve them with the same efficiency as larger, more established entities. This shift could lead to a resurgence in European research initiatives and collaborations.

- Collaboration with Portuguese Space Agency: ATMOS is actively engaging with national space agencies to ensure compliance with emerging regulatory frameworks surrounding reentry missions, paving the way for broader acceptance and integration of its technology.

- Scalable Technology for Diverse Applications: The inflatable heat shield design can be adapted for various payload sizes, even up to the potential return of satellite systems or components of larger rockets, enhancing Europe’s ability to manage and use orbital assets.

- Military and Rapid Response Applications: Partnerships with entities like ARX Robotics signify potential military applications, including rapid response capabilities that could reshape how Europe manages its strategic assets in space.

With increasing investment in space technologies, Europe is gearing up for a renaissance in space exploration and use, centered around reliable and reusable reentry systems. The achievements of companies like ATMOS Space Cargo not only represent technological milestones but also signal a pivotal shift in how space missions are conducted, laying the groundwork for a new era of space logistics.

The future of reentry technology in Europe promises to revolutionize how payloads are returned from space, supporting a diverse set of applications from scientific research to military logistics and beyond. As this sector develops, the contributions of ATMOS and similar innovative companies will play a fundamental role in defining Europe’s place in the global space economy.

Innovations in reusable space capsules are not just about state-of-the-art technology but also about the challenges that come with maximizing efficiency and reliability. As ATMOS Space Cargo continues to advance its Phoenix series, the company faces hurdles that could impact its operational goals and economic viability.

At the heart of these innovations lies the inflatable heat shield, a cutting-edge solution that provides a lightweight alternative to traditional rigid heat shields. This technology not only offers significant weight savings but also enhances the performance of the reentry capsules. However, the practical implementation of such cutting-edge tech must address factors such as thermal protection, structural integrity, and reliability under extreme conditions.

One notable challenge in the development of reusable capsules is ensuring that the inflatable heat shield can withstand the intense environment during reentry, where temperatures can exceed 1,600 degrees Celsius. Ensuring the durability of materials under these conditions requires extensive testing and validation. ATMOS is drawing from decades of aerospace research and empirical data while implementing innovations that enhance the heat shield’s performance. The emphasis on real-world testing is important for building trust among future clients and stakeholders who will rely on this technology.

Another critical area of focus is the vehicle’s reusability. While the company has ambitious plans to make Phoenix fully reusable, the complexities of refurbishing systems after each flight present logistical and economic challenges. Lessons learned from SpaceX’s reusable Falcon 9 and Dragon systems highlight the difficulties of rapid turnaround. Cost-efficiency must be balanced with the high standards of safety and performance required for such missions. ATMOS is taking a pragmatic approach, developing realistic expectations while concurrently aiming for innovation.

To ensure the reliability of their systems, ATMOS has partnered with various suppliers and experts across Europe, using expertise in automotive engineering and aerodynamics. This collaboration not only aids in solving technical challenges but also fosters innovation through knowledge sharing and resource optimization.

- Integration with Existing Systems: One of the innovative strategies ATMOS employs involves designing the Phoenix capsules to be compatible with a variety of launch vehicles. This adaptability is essential for integrating seamlessly into the existing launch ecosystem, enhancing efficiency and maximizing payload versatility.

- Operational Ramping: As ATMOS plans for multiple flights per year, they face the challenge of scaling operations while maintaining quality control. This requires strategic planning and investment in infrastructure to support a higher frequency of launches and recovery operations.

- Testing and Validation: Comprehensive testing regimes are essential for validating aerodynamics, thermal protection, and structural integrity. Real-time telemetry data collection during reentry, as seen with the Phoenix 1 mission, is critical for refining designs and ensuring performance reliability in future missions.

Moreover, the unique design of the Phoenix capsules, influenced by the strategic geometry and balance of forces during reentry, presents another layer of complexity. The asymmetrical shape may cause fluctuations in stability, making precise control during descent crucial. ATMOS’s use of advanced simulations and flight data will contribute to honing their capabilities in this area.

Real-time telemetry during reentry is a game-changer for ensuring the operational success of reusable capsules. Collecting substantial data points from each mission, as evidenced by the 135,000 telemetry points gathered during Phoenix 1’s reentry, informs not just improvements on the Phoenix series but can also contribute to the broader aerospace community. This wealth of information is invaluable for future innovations, enabling the industry to learn from each mission.

Ultimately, ATMOS Space Cargo’s journey exemplifies the interplay of innovation and challenge in the reusable aerospace sector. Each advancement, while exciting, must be tempered with the realities of physics, engineering, and industry demands. The road ahead is marked by a commitment to not only embrace technological breakthroughs but also to navigate the complex landscape of development, testing, and deployment in the quest for reliable and value for your money space logistics.

Stay Informed With the Latest & Most Important News

Previous Post

Next Post

-

01Two Black Holes Observed Circling Each Other for the First Time

01Two Black Holes Observed Circling Each Other for the First Time -

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life -

03Φsat-2 begins science phase for AI Earth images

03Φsat-2 begins science phase for AI Earth images -

04Thermodynamic Constraints On The Citric Acid Cycle And Related Reactions In Ocean World Interiors

04Thermodynamic Constraints On The Citric Acid Cycle And Related Reactions In Ocean World Interiors -

05Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters

05Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters -

06Binary star systems are complex astronomical objects − a new AI approach could pin down their properties quickly

06Binary star systems are complex astronomical objects − a new AI approach could pin down their properties quickly -

07Worlds Next Door: A Candidate Giant Planet Imaged in the Habitable Zone of α Cen A. I. Observations, Orbital and Physical Properties, and Exozodi Upper Limits

07Worlds Next Door: A Candidate Giant Planet Imaged in the Habitable Zone of α Cen A. I. Observations, Orbital and Physical Properties, and Exozodi Upper Limits