Now Reading: Beyond Gravity plans US push after fivefold boost in European solar mechanism output

-

01

Beyond Gravity plans US push after fivefold boost in European solar mechanism output

Beyond Gravity plans US push after fivefold boost in European solar mechanism output

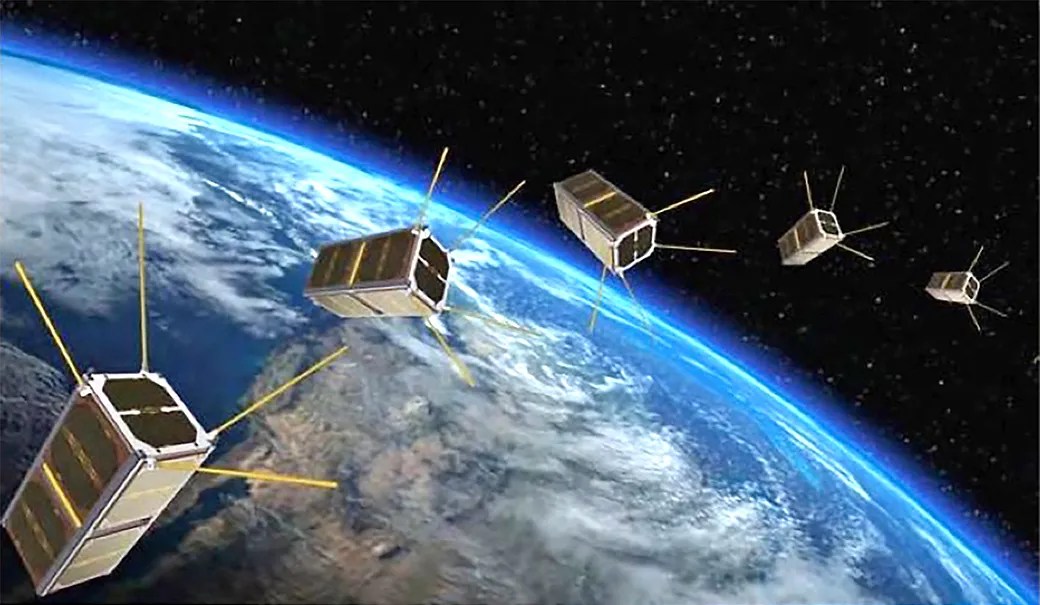

TAMPA, Fla. — Beyond Gravity is weighing expanding solar array drive mechanism production in Florida to support Golden Dome and other U.S. space projects, after doubling manufacturing space in Europe for hardware that keeps satellites pointed toward the sun.

The Zurich-headquartered space systems supplier said Oct. 15 that expanding to 225 square meters of cleanroom space in Switzerland has delivered a fivefold increase in output, enabling production of 200 mechanisms per year amid growing demand for sovereign constellations in Europe.

“This year alone, we have already delivered more units than in the past three years combined,” said Oliver Grassmann, Beyond Gravity’s executive vice president of satellites.

Grassmann said European demand is being driven by IRIS², Europe’s proposed sovereign multi-orbit broadband network, and other planned constellations aimed at strengthening regional independence.

In the United States, Beyond Gravity serves domestic space primes from a 2,000-square-meter facility in Titusville, Florida, and anticipates surging demand linked to Space Development Agency constellation efforts and Golden Dome, the country’s multibillion-dollar missile defense initiative.

Grassmann said the company has another 2,000 square meters of reserve space at the Titusville site near Cape Canaveral.

“In Titusville, we have highly automated our manufacturing and are able to achieve similar efficiency gains like in our newly expanded cleanroom in Switzerland,” he told SpaceNews.

Beyond Gravity supplies a variety of solar array drive mechanisms for spacecraft ranging from microsatellites to large Earth observation and telecommunications platforms.

Customers include NASA’s Artemis lunar program and the European Space Agency’s Hera planetary defense mission that launched in October 2024.

Meeting demand

Alongside the growing importance of space capabilities, shifting market dynamics and the broader industrialization of satellite manufacturing are driving Beyond Gravity to accelerate production of solar array drive mechanisms.

“We expect satellite lifespans to be shorter than in the past due to the prevalence of constellations,” Grassmann said, pointing to a broader shift toward high-volume manufacturing to support rapid replacement and upgrade cycles.

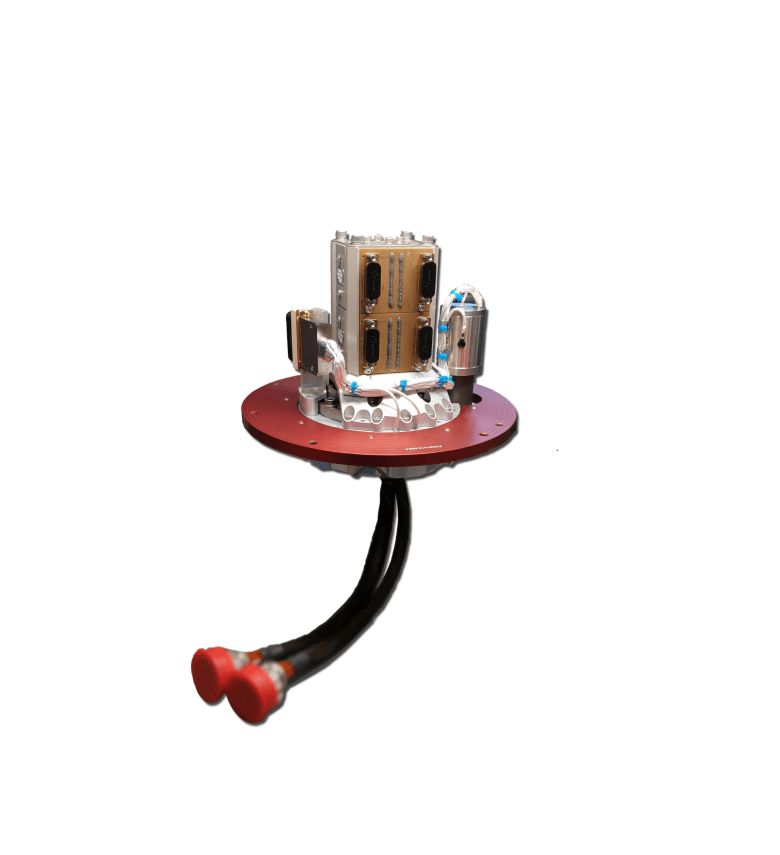

Beyond Gravity is also developing a modular two-axis solar array drive mechanism designed to let solar wings continuously track the sun in more directions, boosting power generation amid the rapidly changing lighting conditions of low Earth orbit. The company says the system could be combined with the company’s existing single-axis products.

One of the biggest challenges in space missions is ensuring a continuous power supply to satellites and spacecraft, according to Alexandra Isele, vice president of mechanical satellite solutions at Beyond Gravity.

The performance of photovoltaic modules can vary significantly depending on the type of solar cell and technology, she said, with specialized multi-junction cells used in space reaching about 30% efficiency.

“By continuously adjusting the solar panels to face the sun, our mechanisms can significantly enhance this efficiency,” she added.

“While standard commercial photovoltaic modules typically have an efficiency of around 15-20%, our mechanisms can help achieve efficiencies of up to 50%.”

Isele said the mechanisms also enable satellites to achieve maximum power output from smaller solar panels.

“Without solar array drive mechanisms, solar panels would need to be significantly larger, leading to higher production and launch costs,” she said.

Beyond Gravity, which is already supplying a two-axis solar array drive mechanism for the NASA Artemis Orion crew capsule, expects to make its new modular system available for orders by mid-next year following further testing.

Stay Informed With the Latest & Most Important News

Previous Post

Next Post

-

01Two Black Holes Observed Circling Each Other for the First Time

01Two Black Holes Observed Circling Each Other for the First Time -

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life -

03Astronomy 101: From the Sun and Moon to Wormholes and Warp Drive, Key Theories, Discoveries, and Facts about the Universe (The Adams 101 Series)

03Astronomy 101: From the Sun and Moon to Wormholes and Warp Drive, Key Theories, Discoveries, and Facts about the Universe (The Adams 101 Series) -

04True Anomaly hires former York Space executive as chief operating officer

04True Anomaly hires former York Space executive as chief operating officer -

05Φsat-2 begins science phase for AI Earth images

05Φsat-2 begins science phase for AI Earth images -

06Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters

06Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters -

07Binary star systems are complex astronomical objects − a new AI approach could pin down their properties quickly

07Binary star systems are complex astronomical objects − a new AI approach could pin down their properties quickly