Now Reading: ExoMars parachutes ready for martian deployment

-

01

ExoMars parachutes ready for martian deployment

ExoMars parachutes ready for martian deployment

21/07/2025

862 views

22 likes

The most complex parachute system to ever deploy on Mars has successfully slowed down an ExoMars mock-up landing platform for a safe touchdown on Earth.

A stratospheric helium balloon lifted a dummy descent module and released it above the Arctic Circle at an altitude of nearly 30 km, triggering the deployment of two large parachutes from their doughnut bags.

“We are happy to confirm that we have a parachute design that can work on Mars – an ambitious system with the largest parachute ever to be flown outside Earth,” says Luca Ferracina, ESA’s ExoMars Entry Descent and Landing Module system engineer.

This high-altitude drop test campaign took place at the Swedish Space Corporation’s Esrange Space Center in Kiruna, northern Sweden, on 7 July.

How to test a Mars landing on Earth

To match the combination of density and speed that the capsule will experience when diving into the thin martian atmosphere – about 1% of the density of Earth’s atmosphere at sea level – the balloon had to fly very high.

The ExoMars parachutes dropped from an altitude of 29 km, or about three times the altitude where commercial aircraft cruise.

The dummy capsule then went into free-fall for about 20 seconds, reaching almost the speed of sound, before deploying the parachutes in turn.

“The combination of velocity and low atmospheric density in this test is exactly the same as what the parachutes will experience on Mars. Testing on Earth is a way to gain confidence and confirm that all the elements perform as expected,” explains Luca.

High-altitude drop tests require complex logistics and strict weather conditions for flight safety. Esrange’s unique facilities and long heritage of stratospheric balloon missions since the early 1970s make it a suitable location for the campaign.

Two are better than one

Landing on Mars is a high-risk endeavour. In just six minutes, the descent module has to decelerate from 21 000 km/h at the top of the planet’s atmosphere to a soft landing to keep its precious cargo, the Rosalind Franklin rover, fit for surface exploration.

Slowing down requires a thermal shield, two main parachutes – each with its own pilot chute for extraction – and a retro-rocket propulsion system triggered 20 seconds before touching the martian surface.

Most of the supersonic velocity will decrease due to the aerodynamic drag of the capsule. The most efficient way to remove the remaining speed for a safe landing is with a combination of parachutes and retro-rockets.

“Using two parachutes allows us to design a strong, medium-sized parachute to decelerate the probe through supersonic speeds and then a much larger, lightweight parachute for the final descent,” explains John Underwood, principal engineer at Vorticity, the UK company entrusted with parachute design and test analysis.

Working in tandem

The first stage main parachute is 15 m-wide, similar to the type of parachutes designed for landing NASA’s Viking Mars spacecraft in 1972. For ExoMars, teams are using a variant designed for the successful ESA Cassini-Huygens mission to Titan, Saturn’s largest moon. This three-stage parachute system still holds the record for the most distant landing from Earth ever attempted.

The second stage main parachute is 35 m-wide and it is formed from a series of rings with gaps in between them. This will be the largest parachute to ever fly on Mars or anywhere in the Solar System besides Earth. Made from over 800 square metres of fabric and more than four kilometres of cord for the suspension lines, it takes around three days to fold it inside its bag.

The meticulous folding of each parachute inside its bag is essential to guarantee a correct deployment.

Storage and design challenges

The parachute system tested in Sweden was already qualified to fly to Mars in 2021, but was stored when the mission was put to a halt due to Russia’s invasion of Ukraine.

“We are running this campaign to confirm our readiness for Mars, and to verify that the parachutes are still performing as expected after the long storage,” explains Luca.

The parachutes are each manufactured from very light fabric with a density of about 40 grams per square metre – about half that of a sheet of paper.

Parachute expertise elevating Europe

While telemetry was delivered in real time during the drop, the Vorticity team will now analyse the data together with high-speed video footage to evaluate the deceleration profile and inflation models.

“Testing on Earth has the advantage that we can obtain much more data and recover the parachutes for inspection after the test,” says John.

The majority of the parachute system has been designed and built in Europe, including components from the Netherlands (the deployment mortars), Italy (parachutes) and Czechia (the parachute container). Thales Alenia Space in France supervised the test campaign as responsible for the parachute assembly system.

Stay Informed With the Latest & Most Important News

Previous Post

Next Post

-

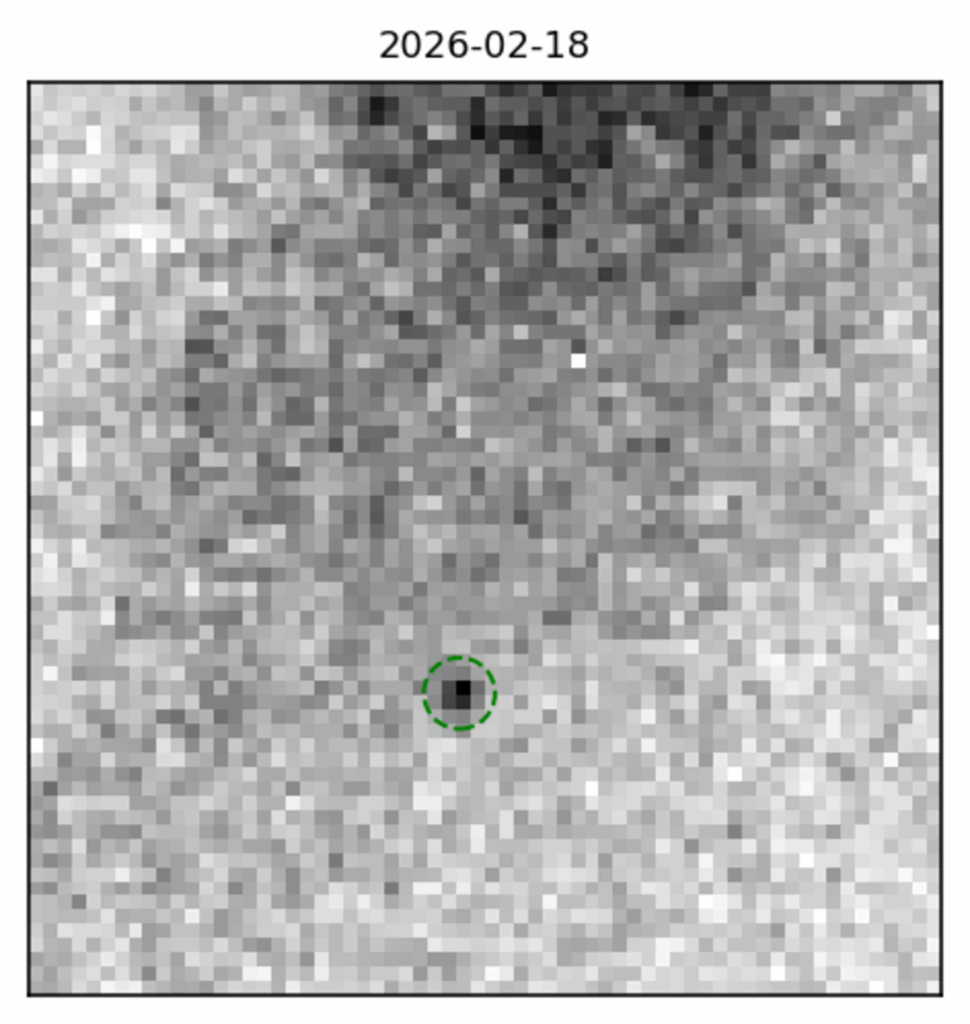

01Two Black Holes Observed Circling Each Other for the First Time

01Two Black Holes Observed Circling Each Other for the First Time -

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life -

03Astronomy 101: From the Sun and Moon to Wormholes and Warp Drive, Key Theories, Discoveries, and Facts about the Universe (The Adams 101 Series)

03Astronomy 101: From the Sun and Moon to Wormholes and Warp Drive, Key Theories, Discoveries, and Facts about the Universe (The Adams 101 Series) -

04True Anomaly hires former York Space executive as chief operating officer

04True Anomaly hires former York Space executive as chief operating officer -

05Φsat-2 begins science phase for AI Earth images

05Φsat-2 begins science phase for AI Earth images -

06Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters

06Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters -

07Binary star systems are complex astronomical objects − a new AI approach could pin down their properties quickly

07Binary star systems are complex astronomical objects − a new AI approach could pin down their properties quickly