Now Reading: Mixing Regolith With Polymer Saves Mass For 3D Printing

1

-

01

Mixing Regolith With Polymer Saves Mass For 3D Printing

Mixing Regolith With Polymer Saves Mass For 3D Printing

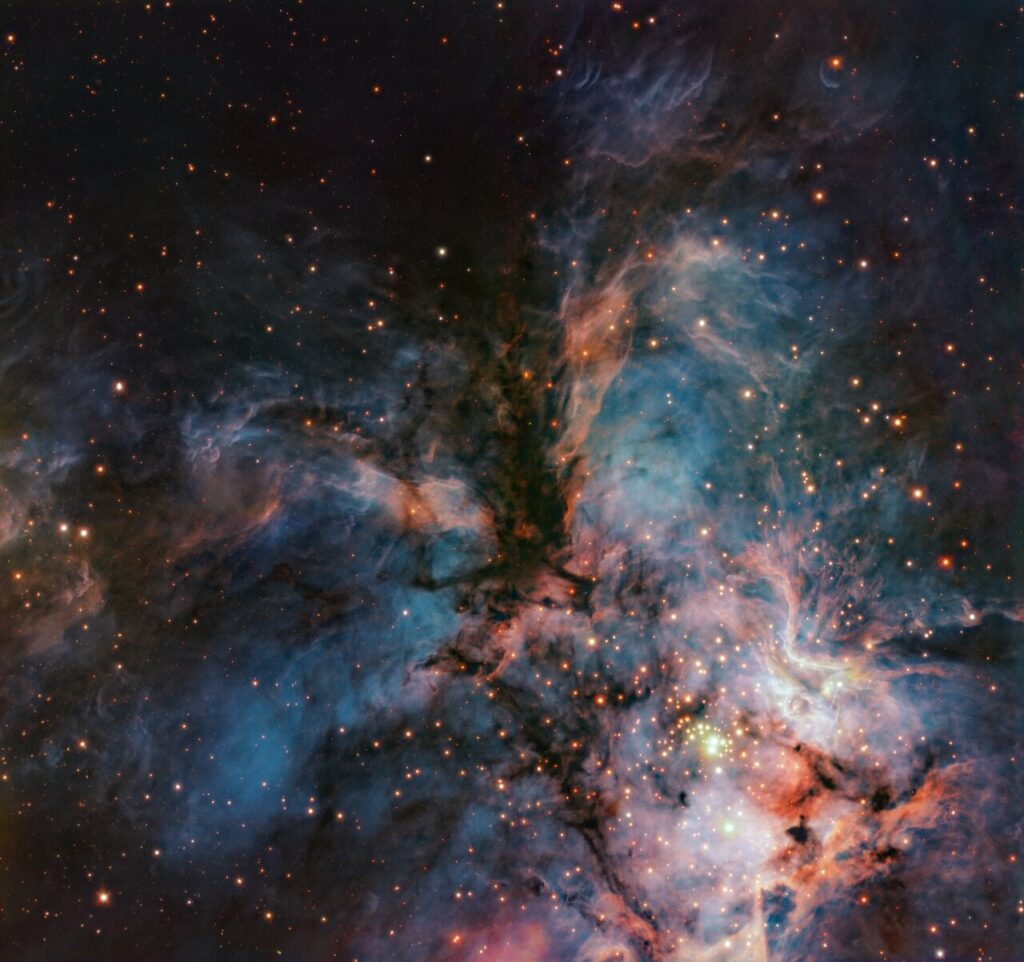

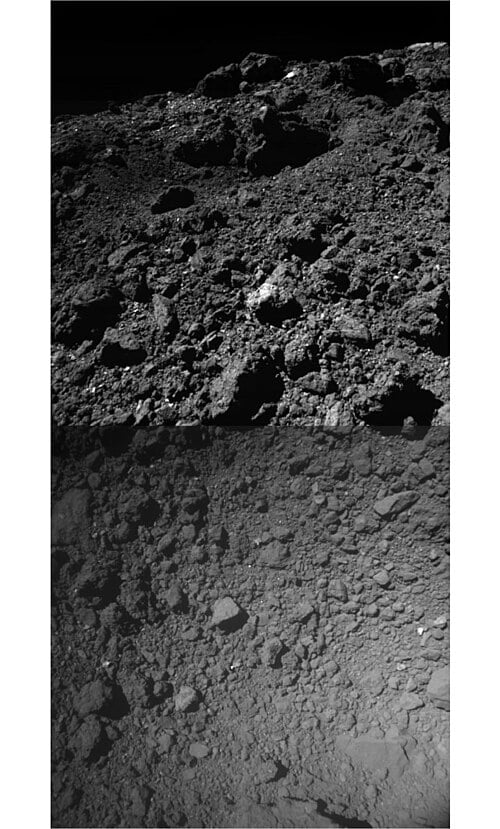

3D printing is going to be a critical technology in space exploration, both for its ability to create almost any object, but also because it can utilize in-situ resources, at least in part. However, the more of those space resources are used in a print, the more the mechanical properties change from that on Earth, leading to problems with tensile or compressive strength. But a new paper from researchers at Concordia University hit a new milestone of how much lunar regolith can be used in a mixed feedstock for additive manufacturing, making it possible to use even more locally sourced material, and saving more launch cost, than ever before.

Stay Informed With the Latest & Most Important News

[mc4wp_form id=314]

Loading Next Post...

Popular Now

-

01Two Black Holes Observed Circling Each Other for the First Time

01Two Black Holes Observed Circling Each Other for the First Time -

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life -

03Astronomy 101: From the Sun and Moon to Wormholes and Warp Drive, Key Theories, Discoveries, and Facts about the Universe (The Adams 101 Series)

03Astronomy 101: From the Sun and Moon to Wormholes and Warp Drive, Key Theories, Discoveries, and Facts about the Universe (The Adams 101 Series) -

04True Anomaly hires former York Space executive as chief operating officer

04True Anomaly hires former York Space executive as chief operating officer -

05Φsat-2 begins science phase for AI Earth images

05Φsat-2 begins science phase for AI Earth images -

06Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters

06Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters -

07Binary star systems are complex astronomical objects − a new AI approach could pin down their properties quickly

07Binary star systems are complex astronomical objects − a new AI approach could pin down their properties quickly

Scroll to Top