Now Reading: New lunar surface simulator in Colorado puts moon machinery to the test

-

01

New lunar surface simulator in Colorado puts moon machinery to the test

New lunar surface simulator in Colorado puts moon machinery to the test

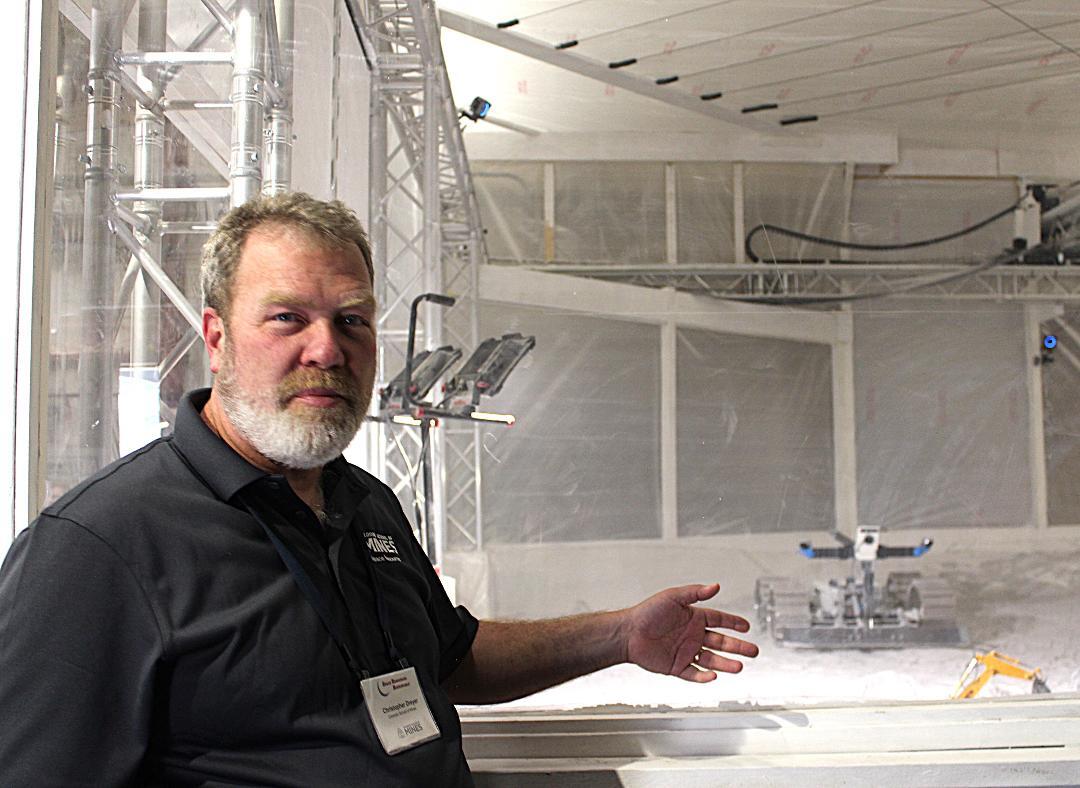

GOLDEN, Colorado — The Colorado School of Mines has built a large simulated moonscape. The specialized facility is being used to test lunar rovers and to evaluate lunar landing and launch pads, excavation gear and other hardware ideas.

It’s all about getting a lunar leg up on how to work effectively with robotic spacecraft on the moon.

“The Mines Lunar Surface Simulator is up and running. We are using it almost every day for one project or another,” said Ian Jehn, an adjunct professor at the school and a structural engineer focused on safe and sound infrastructure for the moon.

Currently, specialists are running rover investigations for the Autonomous Site Preparation: Excavation, Compaction, and Testing project, or ASPECT for short. The work is underway as part of NASA’s Lunar Surface Technology Research (LuSTR) program, Jehn told Space.com, to demonstrate automated lunar site preparation.

ASPECT is a fully autonomous rover, outfitted with equipment for regolith excavation, boulder moving and surface compaction.

Unique challenges

The challenges of building this unique facility were many, said Chris Dreyer, director of engineering at the Colorado School of Mines Center for Space Resources.

“We wanted to build a large facility with a high-quality geotechnical lunar regolith simulant, which presented logistics challenges to make a large amount of simulant at a reasonable cost,” Dreyer said. Over 110 tons (100 metric tons) of lunar simulant fills the large testbed.

The structure itself needed to be dust-tight and waterproof. Within the Mines Lunar Surface Simulator, a gantry system was built to follow a rover’s actions. Frankie Zhu, an assistant professor of mechanical engineering at the School of Mines, developed a rover motion capture system to model rover mobility based on observation.

Building the testbed was a complex task that took more than a year of planning and construction, according to Dreyer. “Having built this, I can understand why there are so few equivalent testbeds in the world,” he said.

Open for innovation

Colorado-based company is building robotic infrastructure, including a rover named Eagle, to help open the moon to further exploration, innovation and commercial activity.

Also interested is Interlune, a Seattle-based startup that aims to be the first company to commercialize natural resources from space, starting with harvesting helium-3 from the moon. Then there’s Outward Technologies, a space mechanisms and systems company advancing critical technologies for extracting resources in space.

Related stories

And some companies are already using the simulated moonscape. For example, during a recent visit to the testbed, Neurospace GmbH of Berlin evaluated its modular rover platform, the HiveR.

Irene Selvanathan, CEO of Neurospace, said the group is identifying the minimum technology required to build a rover that’s inexpensive, affordable and scalable. HiveR is modular, flexible, able to repair itself, and is transferable for use in applications on Earth.

“We’re always looking for opportunities to support technology development coming from startups, established aerospace, and academia,” Dreyer concluded. “There are lots of opportunities to use the testbed for lunar excavation testing, construction, mobility, sensing, dust mitigation and more.”

Stay Informed With the Latest & Most Important News

Previous Post

Next Post

-

01Two Black Holes Observed Circling Each Other for the First Time

01Two Black Holes Observed Circling Each Other for the First Time -

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life -

03Astronomy 101: From the Sun and Moon to Wormholes and Warp Drive, Key Theories, Discoveries, and Facts about the Universe (The Adams 101 Series)

03Astronomy 101: From the Sun and Moon to Wormholes and Warp Drive, Key Theories, Discoveries, and Facts about the Universe (The Adams 101 Series) -

04True Anomaly hires former York Space executive as chief operating officer

04True Anomaly hires former York Space executive as chief operating officer -

05Φsat-2 begins science phase for AI Earth images

05Φsat-2 begins science phase for AI Earth images -

06Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters

06Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters -

07Binary star systems are complex astronomical objects − a new AI approach could pin down their properties quickly

07Binary star systems are complex astronomical objects − a new AI approach could pin down their properties quickly