Now Reading: Pangea Aerospace Unveils Next-Gen Arcos Aerospike Engine

-

01

Pangea Aerospace Unveils Next-Gen Arcos Aerospike Engine

Pangea Aerospace Unveils Next-Gen Arcos Aerospike Engine

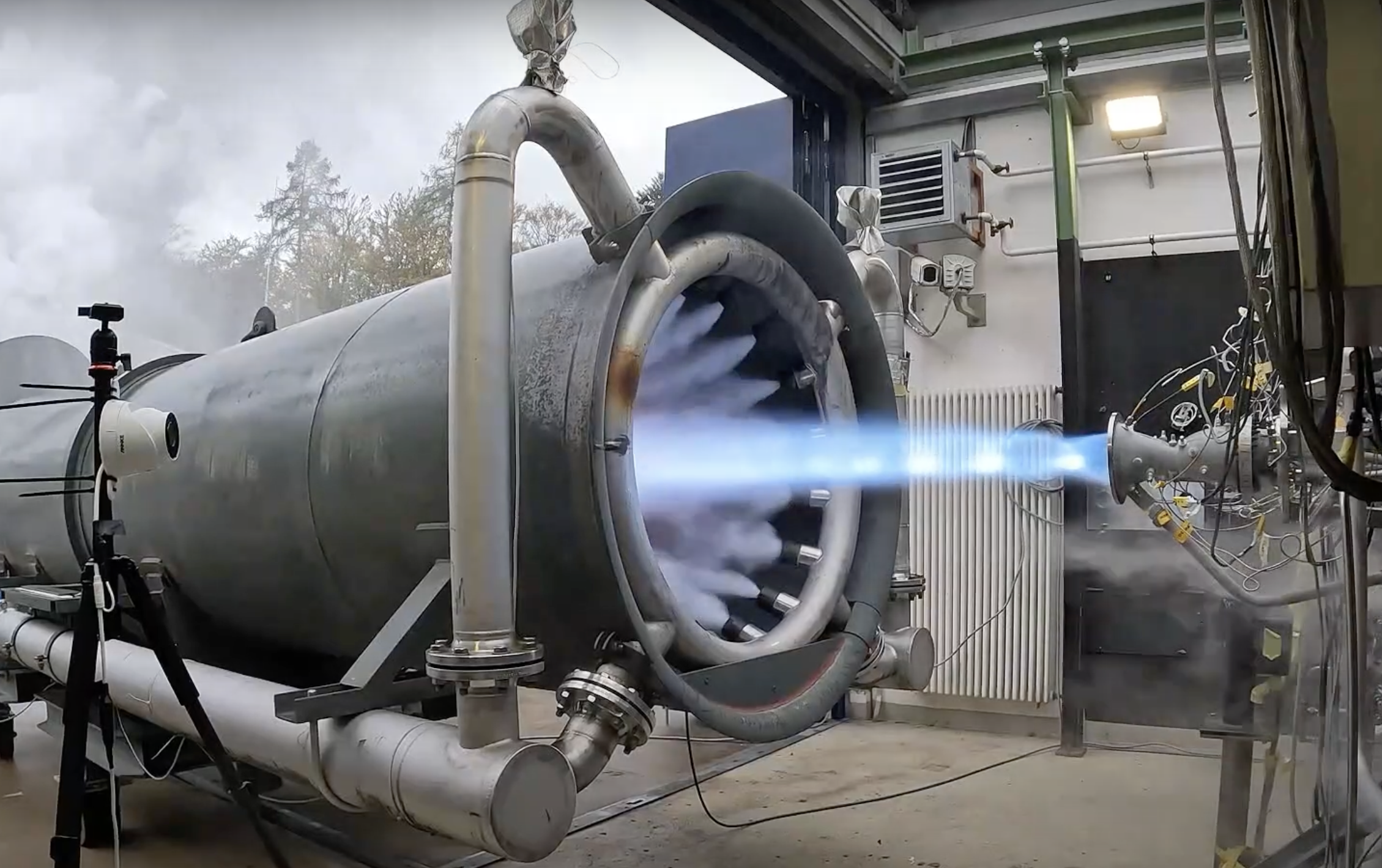

Pangea Aerospace is at the forefront of innovation in aerospike engine technology, a field that has seen interest reignite in recent years due to advancements in materials and manufacturing techniques. The company’s flagship project, the Arcos engine, showcases how modern engineering can revitalize an engine concept that has been theorized for over half a century but rarely realized in practice. Their journey began with the Demonstrator Propulsion 1 engine, which successfully fired as the world’s first methalox aerospike engine in November 2021, garnering significant attention within the aerospace community.

The Arcos engine, which is set to be the world’s first flight-ready aerospike, takes Pangea’s innovative spirit to new heights. Unlike traditional rocket engines optimized for specific flight conditions, the aerospike engine adapts to changing atmospheric pressures, maintaining efficiency across different altitudes. This flexibility is particularly valuable for upper-stage applications where performance is critical. The design evolution from Demo P1 to Arcos represents a leap in ambition, scaling up from 20 kilonewtons to a formidable 750 kilonewtons of thrust. The Arcos measures approximately 3.5 meters in diameter, equivalent to the size of lower stages in existing commercial rockets like Falcon 9, yet it offers a broader and more adaptable range of operational capabilities.

One of the most compelling aspects of Pangea’s technological direction is the integration of reusability into the Arcos engine design. With the space industry pushing toward sustainable practices, having an engine that can be reused multiple times is a game-changer. Argemí emphasizes that reusability isn’t merely an add-on feature; it’s foundational to the design process. The aerospike’s architecture allows for rigorous testing and adaptation, making it possible to withstand numerous flight cycles similar to the Merlin engines used by SpaceX.

Another innovation lies in the propulsion cool down system. The dual regenerative cooling mechanism employed in the Arcos, which utilizes both liquid methane and liquid oxygen, marks a significant shift from traditional methods where only one propellant was used for cooling purposes. This method not only enhances cooling efficiency but also takes advantage of the oxidizer in a way that aligns with the engine’s operational goals. Argemí pointed out, “Historically, rocket engines are just cooled with fuel, but we’re maximizing our cooling potential by incorporating both propellants.” This dual approach reflects an impressive synergy between theoretical concepts and practical engineering solutions.

The manufacturing process for the Arcos engine is equally groundbreaking. Using advanced additive manufacturing techniques, Pangea aims to minimize the number of separate components, ultimately bringing down costs and increasing reliability. Where Demo P1 was made from just two parts, scaling to a larger engine while maintaining simplicity poses a challenge that Pangea is prepared for. By integrating complex systems into fewer parts, the design also increases efficiency and reduces the likelihood of failure points during operation.

Moreover, Pangea’s engineering team has taken on the challenge of optimizing the engine’s performance characteristics. The design incorporates a unique chamber layout with multiple thrusters arranged around its perimeter, allowing for effective thrust vectoring without the need for heavy gimbaling hardware. This simplicity in design enhances the overall robustness and responsiveness of the engine during flight, making it more adaptable to various mission profiles and conditions.

The aerospike’s nozzle, characterized by a high expansion ratio of approximately 180:1, is another aspect where innovation meets practicality. Such a high ratio allows for exceptional performance in a vacuum environment, potentially outperforming existing engines like SpaceX’s Merlin vacuum variant. Argemí’s insight that the aerospike acts as “a performance generator rather than a thrust generator,” encapsulates the shift in thinking that Pangea represents. The goal is not just to increase raw thrust but to leverage the aerospike’s unique properties to create a more efficient trajectory for payloads.

Pangea’s path forward reflects an industry moving toward efficiency and sustainability. With the Arcos engine targeting its first flight by the end of the decade, Pangea Aerospace stands as a beacon of innovation in rocketry. The integration of modern technologies, combined with a renewed interest in aerospike design, positions them to redefine propulsion systems for the next generation of space exploration and commercial endeavors.

The development of aerospike engines, while promising considerable benefits, is not devoid of significant challenges that engineers like those at Pangea Aerospace must navigate. One of the foremost hurdles in aerospike design lies in thermal management. The unique structure of an aerospike, particularly its wide throat area where the highest heat flux occurs, complicates the cooling process. Traditional bell-shaped nozzles, with their smaller throat, allow for simpler cooling solutions, as less mass flow is required. However, the aerospike’s geometry demands a high mass flow rate to efficiently manage these extreme temperatures.

Pangea’s innovative solution to this issue is the implementation of a dual regenerative cooling system. This approach utilizes both liquid methane and liquid oxygen to cool various sections of the engine, maximizing the cooling capacity by using the oxidizer, which is typically not the most efficient coolant. Argemí explains, “We’re using both propellants to cool it down because, historically, rocket engines are just cooled with fuel.” This idea reflects a remarkable integration of ecological considerations into the engineering process, as it not only enhances performance but also fits well with a sustainable operational ethos.

Another critical challenge is the complexity and cost associated with manufacturing aerospikes. Traditional manufacturing methods may result in high costs and longer lead times, making the arousal of aerospike technology commercially challenging. To address this, Pangea has embraced advanced additive manufacturing techniques that allow for the consolidation of parts into fewer, more complex components. For example, while the Demo P1 engine was crafted from just two parts, scaling up to the Arcos engine requires a careful balance between functionality and manufacturability. Argemí notes that even with increased thrust capabilities, about 60% to 70% of the Arcos engine still benefits from this part consolidation, leading to greater reliability and efficiency during production.

The design of the Arcos engine also embodies a sophisticated approach to maximizing thrust vectoring while minimizing mechanical complexity. Its unique architecture, composed of multiple thrusters arranged in a circular pattern, facilitates effective control during flight without the need for cumbersome gimbaling mechanisms. This design philosophy embraces simplicity: by connecting thrust loads directly to the second stage, the entire setup becomes more robust and responsive. Argemí highlights that this feature not only streamlines the design but also enhances its adaptability to varying rocket diameters, paving the way for greater compatibility with diverse launch platforms.

Moreover, the aerospike’s high expansion ratio—approximately 180:1—poses additional opportunities and risks. While it suggests exceptional performance in vacuum conditions, aligning this design feature with reliable ground testing and real-world operational demands poses its own set of engineering challenges. As the aerospike adapts to ambient pressure, it shows promise for maintaining performance across altitudes, a vital capability for upper-stage applications. This duality—balancing theoretical efficiency with practical implementation—represents a significant leap forward in propulsion technology.

Pangea has also dedicated efforts to address issues related to component testing and integration. With the complex configurations required for the Arcos engine, the importance of thorough testing cannot be overstated. Incorporating lessons learned from the Demo P1 engine, the team is using computational fluid dynamics (CFD) simulations and real-world wind tunnel tests to refine engine performance under various conditions. Argemí notes, “We’re targeting our first flight before the end of this decade,” highlighting the importance of rigorous validation processes in ensuring that the Arcos engine meets its ambitious performance targets.

In addition to these technical challenges, the aerospace industry is facing external pressures regarding sustainability and environmental impact. Pangea has taken conscious steps towards sustainability, steering clear of traditional propellant options like hydrazine in favor of less toxic alternatives that still offer excellent performance. By offering engines like U-Nyx, which utilizes High-Test Peroxide (HTP) and Jet A-1 fuel, the company aims to align with broader industry initiatives toward safer and more environmentally friendly practices.

While the journey to realize the potential of aerospike engines is fraught with challenges, Pangea Aerospace’s strategic approach to innovation, testing, and sustainable practices offers a glimpse of a new era in rocket propulsion. The ongoing advancements in the Arcos engine development reflect a holistic vision of not only developing a revolutionary engine but also cultivating a responsible and effective pathway for the future of space exploration.

Stay Informed With the Latest & Most Important News

Previous Post

Next Post

-

01Two Black Holes Observed Circling Each Other for the First Time

01Two Black Holes Observed Circling Each Other for the First Time -

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life -

03Astronomy 101: From the Sun and Moon to Wormholes and Warp Drive, Key Theories, Discoveries, and Facts about the Universe (The Adams 101 Series)

03Astronomy 101: From the Sun and Moon to Wormholes and Warp Drive, Key Theories, Discoveries, and Facts about the Universe (The Adams 101 Series) -

04Φsat-2 begins science phase for AI Earth images

04Φsat-2 begins science phase for AI Earth images -

05Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters

05Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters -

06True Anomaly hires former York Space executive as chief operating officer

06True Anomaly hires former York Space executive as chief operating officer -

07Thermodynamic Constraints On The Citric Acid Cycle And Related Reactions In Ocean World Interiors

07Thermodynamic Constraints On The Citric Acid Cycle And Related Reactions In Ocean World Interiors