Now Reading: SpaceX accelerates Starship launch pad upgrades as preparations for future missions intensify

-

01

SpaceX accelerates Starship launch pad upgrades as preparations for future missions intensify

SpaceX accelerates Starship launch pad upgrades as preparations for future missions intensify

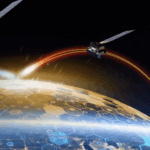

As SpaceX accelerates its production and testing of Starship vehicles and engines, significant advancements are being made in the associated launch infrastructure. The company is focusing on enhancing its launch capabilities at various sites, including Pad 2 at Starbase in Texas and Launch Complex 39A at Kennedy Space Center in Florida, even as it undertakes major renovations at Pad 1.

At Starbase’s Pad 2, located in South Texas, SpaceX teams have ramped up testing, particularly focusing on the methane infrastructure and service connections critical to the upcoming launches. Recent developments include the installation of middle hood sections for booster quick disconnect systems, which will better protect propellant and fluid lines. While extensive welding has not yet begun, the current setup is expected to facilitate trials integral to the launch pad’s functionality.

Significantly, these developments are paving the way for critical assessments of the water deluge system, which plays an important role during liftoff. Initial tests on the system have already taken place, enhancing preparations for launches. The top deck of Pad 2 has recently undergone purging to eliminate any obstructions, and further evaluations of flame containment systems are underway. With most of the service structure completed, only the scaffolding retrieval remains before full-scale testing can begin.

Additionally, SpaceX has been running tests on the newer clamp load test rig designed to evaluate the effectiveness of the clamps that hold the rocket during launch. This rig, known colloquially as the “ibeproofin’” rig, has undergone several positional adjustments to analyze the load on different clamps. Its removal from the site may indicate that Booster 18, the next prototype, is on the way for further assessments.

In recent updates, enhancements have been noted on Pad 2’s tower, with fresh wiring and hydraulics being integrated leading to the quick disconnect arm. Adjustments in design are being made to account for the Starship’s increased dimensions, as the new arm will be positioned lower than its predecessor to accommodate the unique design of the pad.

Simultaneously, the active demolition of Pad 1 is in full swing as SpaceX clears the area for upgrades. Heavy machinery and precision cutting methods have been employed to dismantle the launch mount, stripping it down to its foundational legs and essential hardware. The process is expected to transform the site significantly, marking a new chapter for the Starship program.

In Florida, at Kennedy Space Center’s Launch Complex 39A, work continues at a steady pace. Recent deliveries of materials, including pipes and hardware, facilitate the construction of new systems for the launch infrastructure. Plans are in place for additional components like liquid oxygen tanks to arrive soon. Moreover, construction at the adjacent Giga Bay is progressing, with assembly underway for two tower cranes that will support expansion efforts.

Lastly, while the Environmental Impact Statement process for the two planned Starship pads at Space Launch Complex 37 is ongoing, delays due to a government shutdown have pushed back timelines for project completion. With the government now back to work, officials remain hopeful that necessary approvals will be secured soon, allowing foundation work at the complex to commence.

Overall, as SpaceX intensifies its preparations for future Starship missions, the transformation of its launch facilities positions the company for its next phase of ambitious space exploration objectives.

Stay Informed With the Latest & Most Important News

Previous Post

Next Post

-

01Two Black Holes Observed Circling Each Other for the First Time

01Two Black Holes Observed Circling Each Other for the First Time -

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life -

03Astronomy 101: From the Sun and Moon to Wormholes and Warp Drive, Key Theories, Discoveries, and Facts about the Universe (The Adams 101 Series)

03Astronomy 101: From the Sun and Moon to Wormholes and Warp Drive, Key Theories, Discoveries, and Facts about the Universe (The Adams 101 Series) -

04True Anomaly hires former York Space executive as chief operating officer

04True Anomaly hires former York Space executive as chief operating officer -

05Φsat-2 begins science phase for AI Earth images

05Φsat-2 begins science phase for AI Earth images -

06Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters

06Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters -

07Binary star systems are complex astronomical objects − a new AI approach could pin down their properties quickly

07Binary star systems are complex astronomical objects − a new AI approach could pin down their properties quickly