Now Reading: SpaceX Advances Block 3 Development with Major Hardware and Testing Updates

-

01

SpaceX Advances Block 3 Development with Major Hardware and Testing Updates

SpaceX Advances Block 3 Development with Major Hardware and Testing Updates

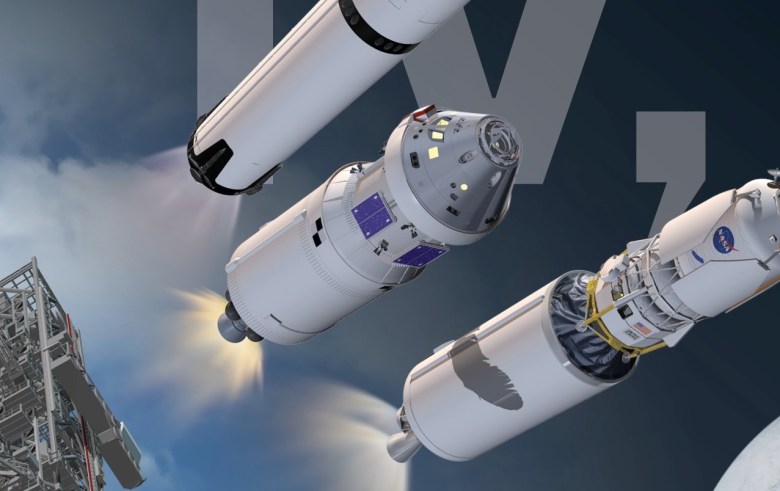

SpaceX has been making significant strides in the development of its Block 3 hardware, showcasing a blend of innovation and strategic planning as it preps for the ambitious goals ahead. The centerpiece of this effort is Ship 39, the first vehicle emerging from the Block 3 production line, which recently revealed glimpses of its evolving form amidst the bustling environment at Starbase. The visual updates highlight that the construction team is nearing completion on the crucial Thermal Protection System (TPS), fundamental for ensuring the spacecraft’s integrity during re-entry and landing.

The process of applying TPS is meticulous; most of Ship 39’s body, including the critical flaps, is now covered, marking a pivotal point as preparations ramp up. This progress is a testament to SpaceX’s commitment to high-quality engineering—each tile placed is integral to the ship’s overall performance. As the vehicle approaches the necessary tiling density required for stacking, the anticipation builds around the next phases of assembly. Questions abound, particularly regarding the assembly sequence: will SpaceX begin with the main tank or the nose section? This decision will significantly impact the production timeline and efficiency as the company aims to escalate its launch cadence to unprecedented levels.

Meanwhile, an intriguing development on the booster side has emerged—a specialized landing tank for a Block 3 Super Heavy booster has been spotted. This sophisticated component, nestled within the liquid oxygen (LOX) tank, is designed to minimize propellant sloshing during landing maneuvers. The significance of this design cannot be overstated; in scenarios where the main tanks are nearly empty, any movement can disrupt the flow of fuel to the Raptor engines, jeopardizing controlled descents and increasing the risk of mishaps during landing.

The landing tank features a robust outer shell engineered for LOX storage, complemented by an internal methane transfer tube, which is visually identifiable as a capped structure near the top. This innovative design could serve dual purposes: as the aft section for Booster 18 currently under development or potentially as a dedicated test article, demonstrating SpaceX’s methodical approach to validating Block 3 components individually before full-scale integration.

In addition to these advancements in hardware, activity surrounding the Mega Bay 1 has revealed further insights into the structural testing efforts. Something noteworthy has been observed regarding an old structural testing rig, colloquially referred to as the “can crusher.” This rig was repositioned inside the bay alongside a test article for the Booster Hot Staging Ring and has been modified to assess the integrated hot staging design. Images from recent days have confirmed that the hot staging ring test article is now mounted atop the can crusher, using vertical force application to evaluate the structure’s integrity—a critical precursor to installing a similar ring on Booster 18.

Enhancing this rigorous testing process is the introduction of a new “Booster Block 3 Loadspreader,” a design that promises to optimize the testing efficiencies further. This device integrates seamlessly with the hot staging ring’s strakes, facilitating smoother lifts of the booster and ensuring meticulous attention to structural assessments throughout the development process.

The heart of SpaceX’s engineering prowess continues to beat steadily at the McGregor facility, where the Raptor engines are undergoing rigorous testing in preparation for the next phase of the Starship program. In a remarkable week of activity, SpaceX conducted a series of twenty engine tests, revealing not just the relentless drive for improvement, but also a deep commitment to reliability and performance in the face of the challenges posed by reusable rocket technology.

Among the highlights was a standout achievement at the Raptor South Stand, now fully dedicated to the Raptor 3 variants. This notable test reached an impressive 354-second burn— a record for that particular stand and tantalizingly close to the all-time Raptor record. This nearly six-minute duration mirrors the maximum required in actual flight scenarios, indicating that the Raptor 3 is on the cusp of moving into its final qualification phase ahead of full production. Such milestones are critical, as they provide valuable data that informs not just the performance of the Raptor engines, but also the overall trajectory of the Starship program.

However, the path of innovation is often fraught with hurdles. Not all tests yielded the desired outcomes; a Raptor 3 test firing on the Vertical Stand was abruptly halted after just 40 seconds due to an explosive shutdown. Whether this was an intentional part of the testing process— as SpaceX frequently conducts stress tests to push engines to their limits— remains unclear. Nevertheless, the incident resulted in a temporary halt of activities at the stand, contributing to a decrease in overall test counts for the week. This scenario serves as a reminder of the complexities involved in pushing the boundaries of rocket propulsion technology.

Merging engineering might with artistic expression, NSF captured stunning slow-motion footage of various tests, including the melodious roar of the Raptor engines and the sleek lines of the Merlin engines during their static fire tests. The beauty of these engines in action is paired with the practical realities of testing, as all activities adhered strictly to FAA regulations, safeguarding the area and maintaining compliance throughout the challenging work.

The importance of engine testing extends beyond mere performance metrics— it is a vital aspect of the overall mission to refine the Starship design and architecture, which requires a thorough understanding of engine behavior under various conditions. Each engine test serves as a building block in the edifice of knowledge SpaceX consolidates as it progresses toward its goal of interplanetary exploration.

Looking ahead, the ongoing developments in engine testing will seamlessly tie into SpaceX’s broader objectives, including the anticipation surrounding the Block 3 architecture. These engines will play an important role in the upcoming missions, including the imminent Flight 11 of Starship, which marks the final launch of the Block 2 vehicle. With the relentless spirit of innovation that defines SpaceX, the progress at McGregor is not just impressive; it’s a beacon of hope for the future of space travel.

Stay Informed With the Latest & Most Important News

Previous Post

Next Post

-

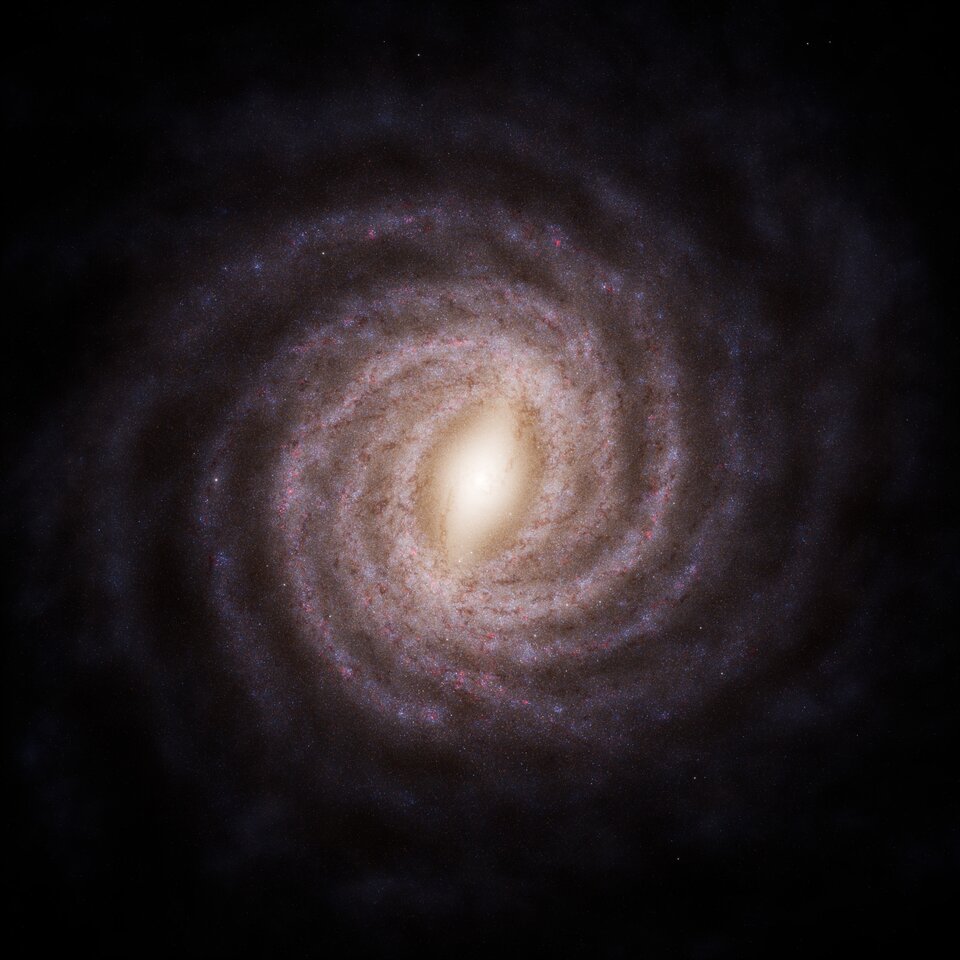

01Two Black Holes Observed Circling Each Other for the First Time

01Two Black Holes Observed Circling Each Other for the First Time -

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life

02From Polymerization-Enabled Folding and Assembly to Chemical Evolution: Key Processes for Emergence of Functional Polymers in the Origin of Life -

03Astronomy 101: From the Sun and Moon to Wormholes and Warp Drive, Key Theories, Discoveries, and Facts about the Universe (The Adams 101 Series)

03Astronomy 101: From the Sun and Moon to Wormholes and Warp Drive, Key Theories, Discoveries, and Facts about the Universe (The Adams 101 Series) -

04True Anomaly hires former York Space executive as chief operating officer

04True Anomaly hires former York Space executive as chief operating officer -

05Φsat-2 begins science phase for AI Earth images

05Φsat-2 begins science phase for AI Earth images -

06Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters

06Hurricane forecasters are losing 3 key satellites ahead of peak storm season − a meteorologist explains why it matters -

07Binary star systems are complex astronomical objects − a new AI approach could pin down their properties quickly

07Binary star systems are complex astronomical objects − a new AI approach could pin down their properties quickly